Scope of Application: The GWZC-9586 low-voltage generator protection relay is suitable for backup protection of 400V low-voltage generators below 1000kW. It can be installed in panels or locally in switchgear.

Protection Functions(ANSI): 50 | 51 | 50N | 51N | 50I | 50V | 32 | 81U | 80O | 59 | 27

Monitoring and Control Functions: • 14 channels of remote signal input collection; • 8 channels of relay outputs; • Event SOE recording

Communication Functions: • 2 Ethernet interfaces (supporting Ethernet 103 protocol, optional); 1 RS485 communication port (supporting Modbus-RTU protocol)

Product Overview: GWZC-9605 Cable Insulation Monitoring Device is designed to collect real-time parameters such as leakage current, partial discharge, and temperature of cables, enabling comprehensive evaluation of insulation status and timely warning of abnormalities. This facilitates a shift from passive repair to proactive prevention in maintenance practices, ensuring the safe operation of the power system.

Product functions(ANSI): Cable Insulation Monitoring (ANSI 64)

Communication functions: IEC61850 | IEC 60870-5-103 | MODBUS RTU | 2× Ethernet Ports | 2× RS-485

Introduction: The partial discharge online monitoring system uses IoT and smart sensors to monitor power equipment without power outage. It employs TEV, AE, UHF, and temperature sensors to intelligently detect transformers, GIS, switchgear, and cables.

Composition: Includes monitoring software, host, sensors, PC, and mobile app.

Functions: Realtime monitoring and analysis of substation/power plant equipment to prevent faults.

Scope of Application: Primarily targets temperature measurement at key locations of primary equipment in substations, such as surfaces of dry-type transformers, box-type transformers, disconnect switches, conductive busbar joints, cable joints, and high-voltage switchgear contacts.

Main Functions:Monitors electrical equipment temperature in real time, detects abnormalities, analyzes data, and triggers automatic alarms to prevent accidents.

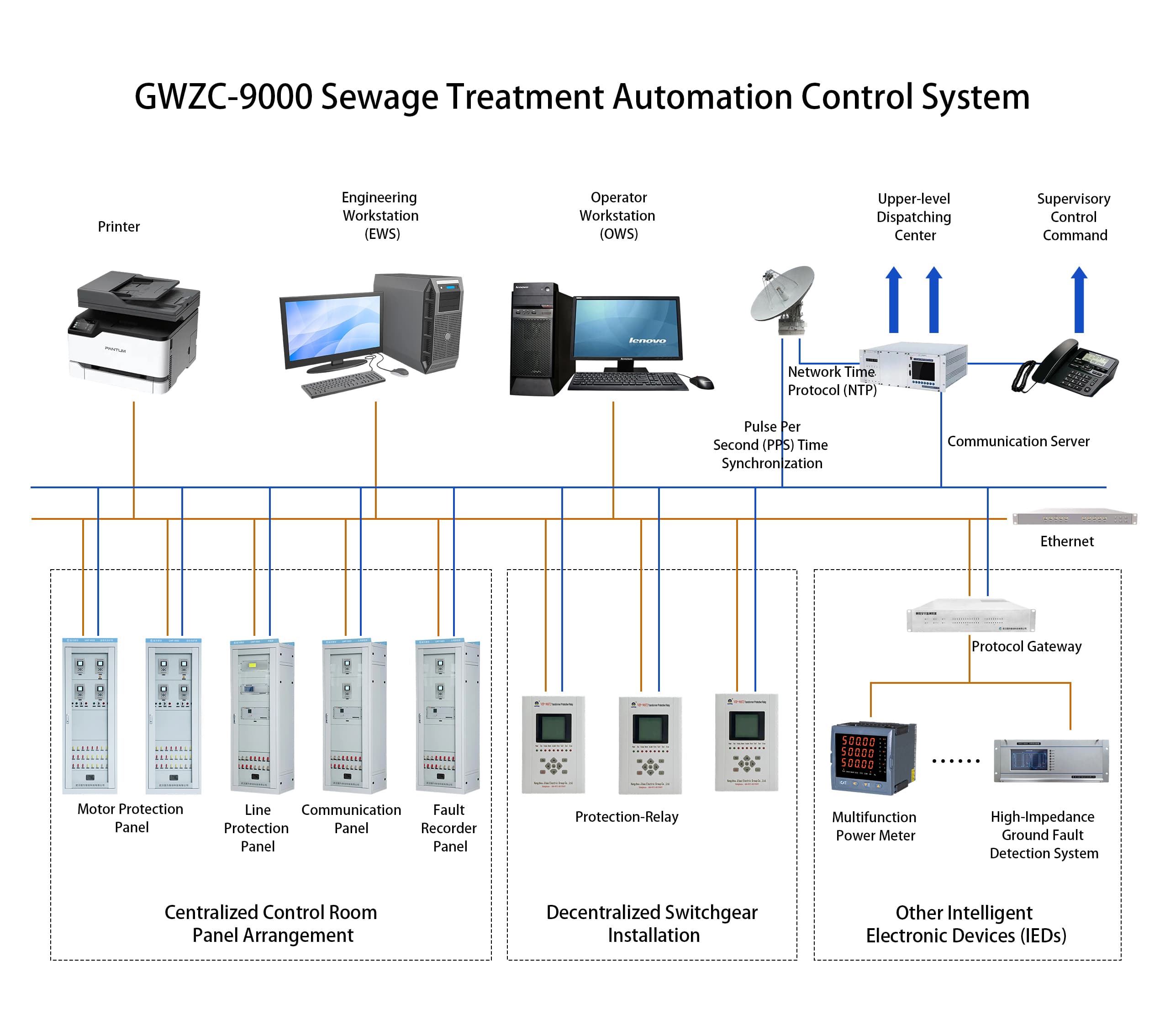

The GWZC-9000 sewage treatment automation control system integrates advanced control, monitoring, and protection technologies to enhance the efficiency, reliability, and safety of the sewage treatment process. The system automates key functions such as pump station control, flow regulation, water quality monitoring, and fault detection, reducing manual intervention and minimizing downtime. It employs intelligent protection relays, programmable logic controllers (PLCs), and remote terminal units (RTUs) to collect realtime data on water quality, flow rate, and equipment status.

The GWZC-9000 Drainage Pumping Station Automation System integrates PLC controllers, level sensors, and remote telemetry to automate floodwater management. It monitors realtime water levels, pump status, and flow rates using ultrasonic sensors and IoT gateways, triggering pump sequencing during heavy rainfall or rising tides. SCADA enables remote operation via HMI dashboards, while embedded algorithms optimize pump runtime to prevent overflow and reduce energy costs. With fault diagnostics (motor failures, blockage alerts) and SMS/cloud alarms, it minimizes urban flooding risks.

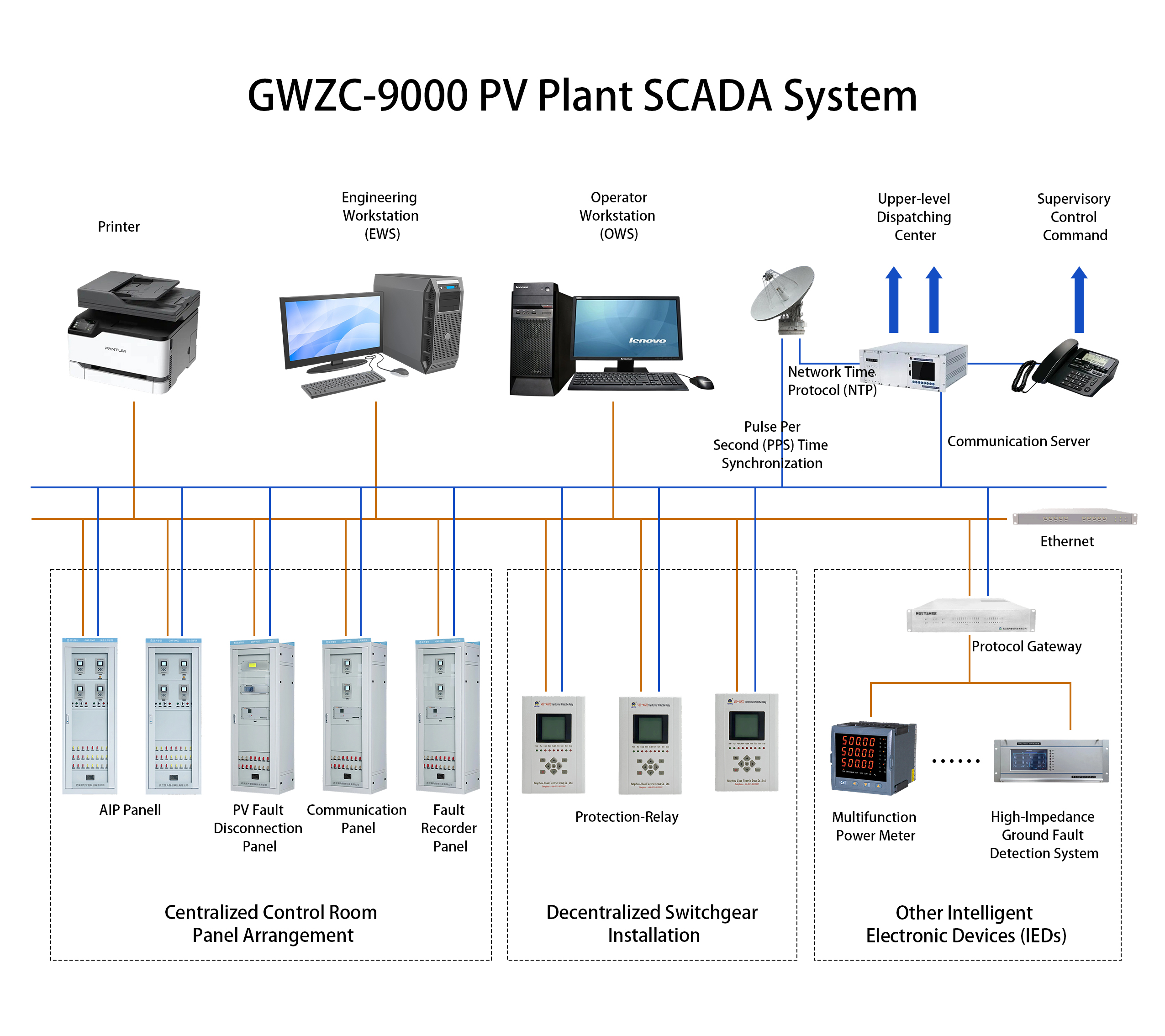

The GWZC-9000 integrated automation system for photovoltaic power plants incorporates advanced control, monitoring, and protection technologies to enhance operational efficiency, reliability, and safety. The system automates critical functions such as circuit breaker operation, load switching, fault detection, and isolation, reducing manual intervention and minimizing downtime. It utilizes intelligent protection relays, programmable logic controllers (PLCs), and remote terminal units (RTUs) to collect real-time data on voltage, current, power quality, and equipment status.

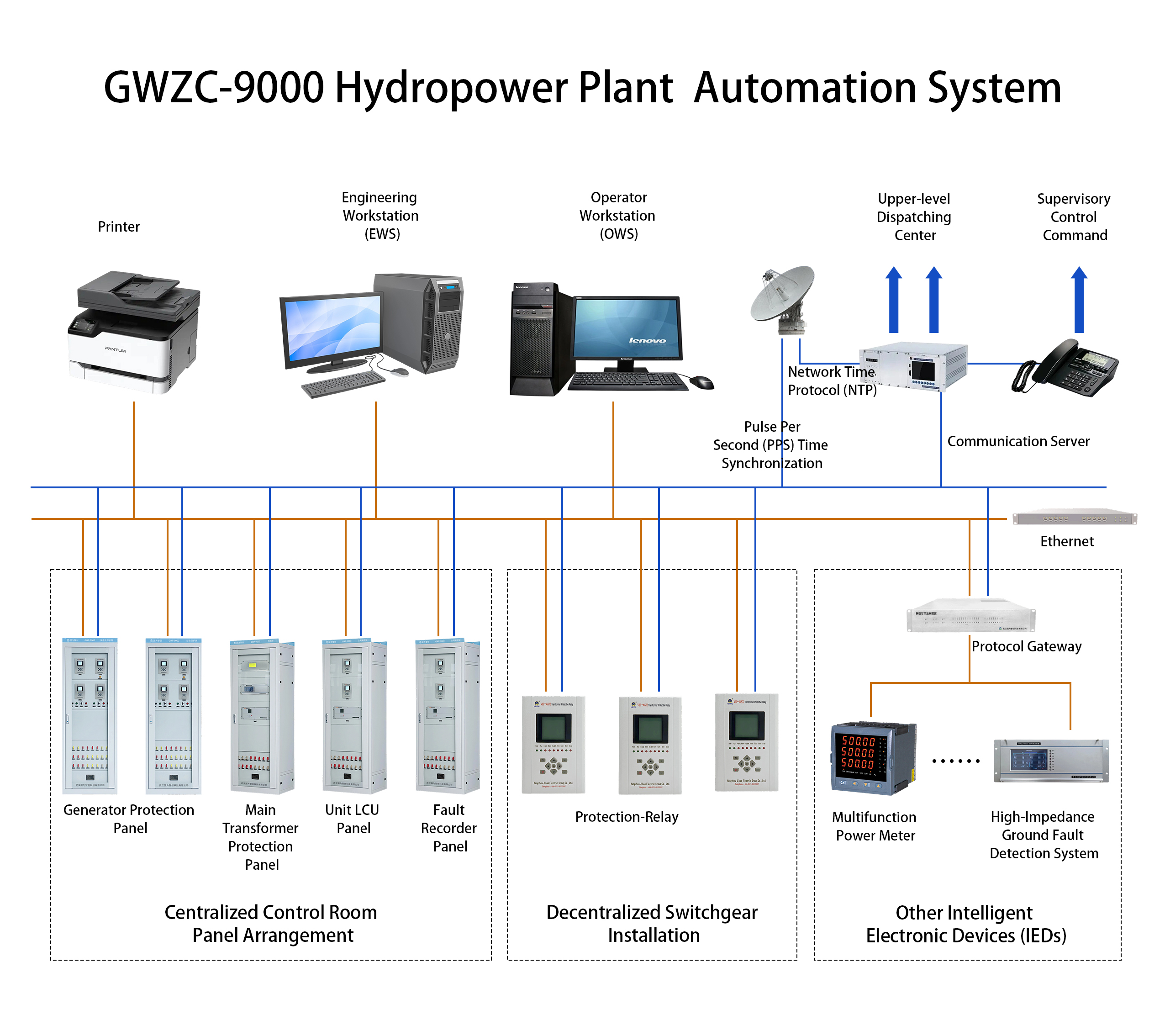

The GWZC-9000 hydropower plant automation system incorporates advanced control, monitoring, and protection technologies to enhance operational efficiency, reliability, and safety. It automates critical functions such as generator control, load distribution, fault detection, and isolation, minimizing manual intervention and reducing downtime. The system utilizes intelligent protection relays, programmable logic controllers (PLCs), and remote terminal units (RTUs) to collect real-time data on voltage, current, power quality, and equipment status.

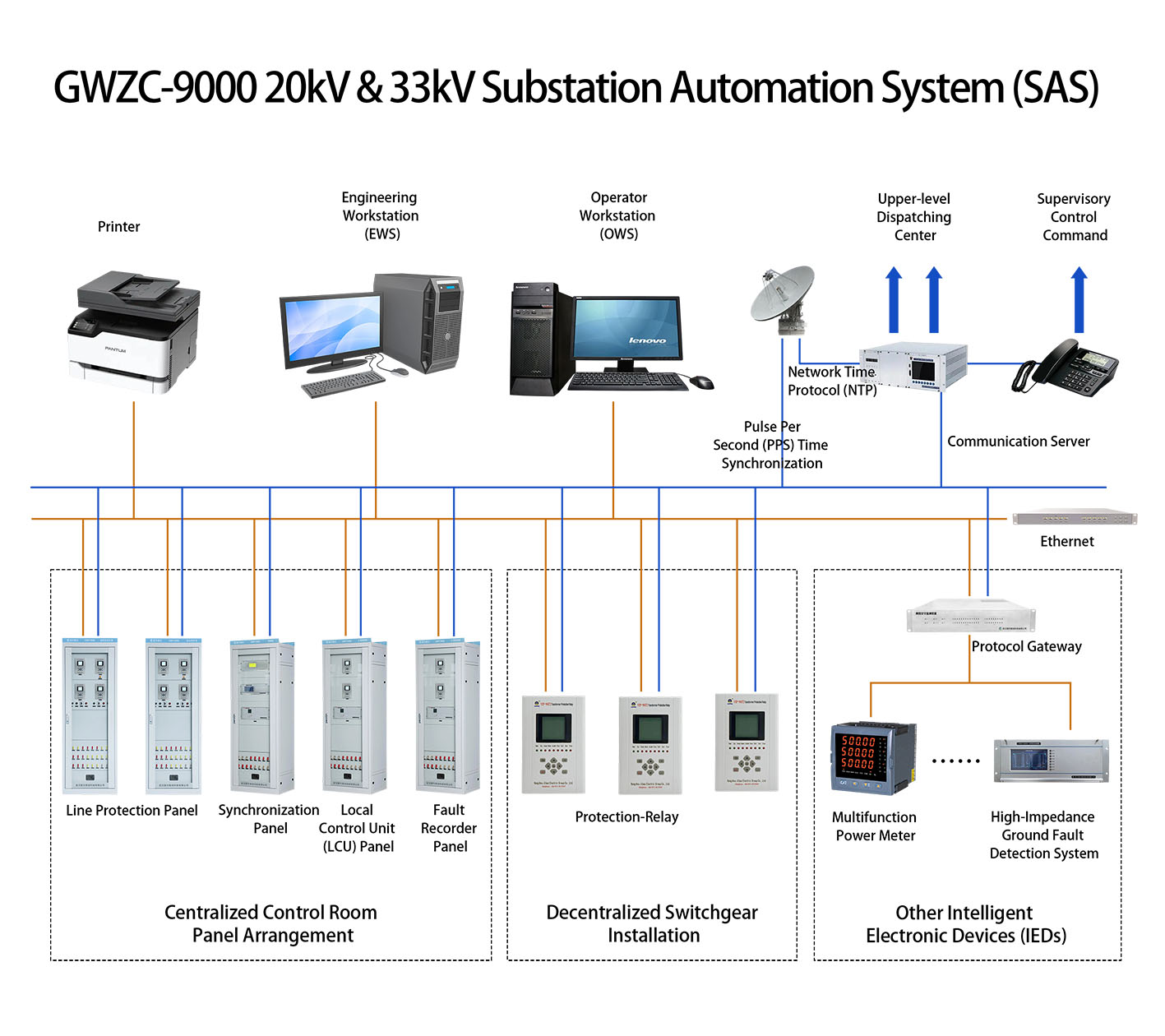

The GWZC-9000 20kV & 33kV Substation Automation System (SAS) integrates intelligent protection relays, PLCs, and RTUs to automate critical functions such as circuit breaker control, fault detection, load management, and power quality monitoring. This system ensures real-time data acquisition, remote operation, and rapid fault isolation, minimizing downtime and improving grid resilience.

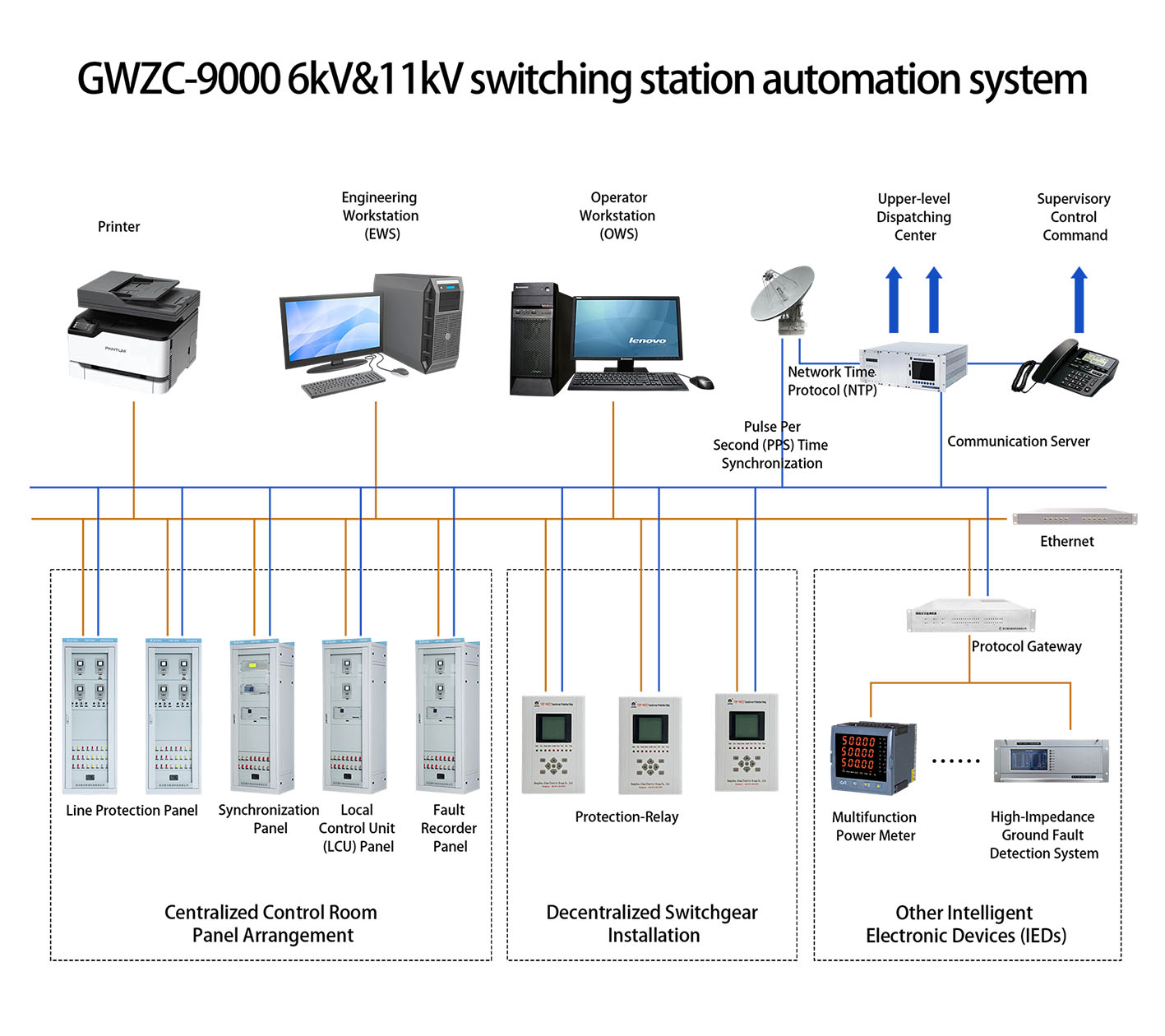

The GWZC-9000 6kV & 11kV switching station automation system integrates advanced control, monitoring, and protection technologies to enhance the efficiency, reliability, and safety of medium-voltage power distribution. This system automates key functions such as circuit breaker operation, load switching, fault detection, and isolation, reducing manual intervention and minimizing downtime. It employs intelligent electronic devices (IEDs), programmable logic controllers (PLCs), and remote terminal units (RTUs) to collect real-time data on voltage, current, power quality, and equipment status.