Gas-insulated switchgear (GIS) primarily refers to a cabinet for housing switching devices, enclosed by a metal steel plate shell with doors or cover panels to allow access for installation and operation. The switchgear includes various components such as disconnectors, load switches, earthing switches, etc., each serving specific functions.

Disconnector (Isolator)

A disconnector provides electrical isolation by separating two sections of a circuit to meet safety requirements. It ensures a safe electrical clearance between the two parts, allowing them to operate independently and safely even at different voltages. For instance, in a dual-power supply incoming isolation cabinet, disconnectors enable two busbar sections to operate separately.

Disconnectors must provide a visible break. For a device suitable for isolation, the clearance in the open position must meet the isolation requirements, and one or more of the following methods must be provided to indicate the position of the main contacts:

Position indication of the operating mechanism;

An independent mechanical indicator;

Direct visibility of all main contacts.

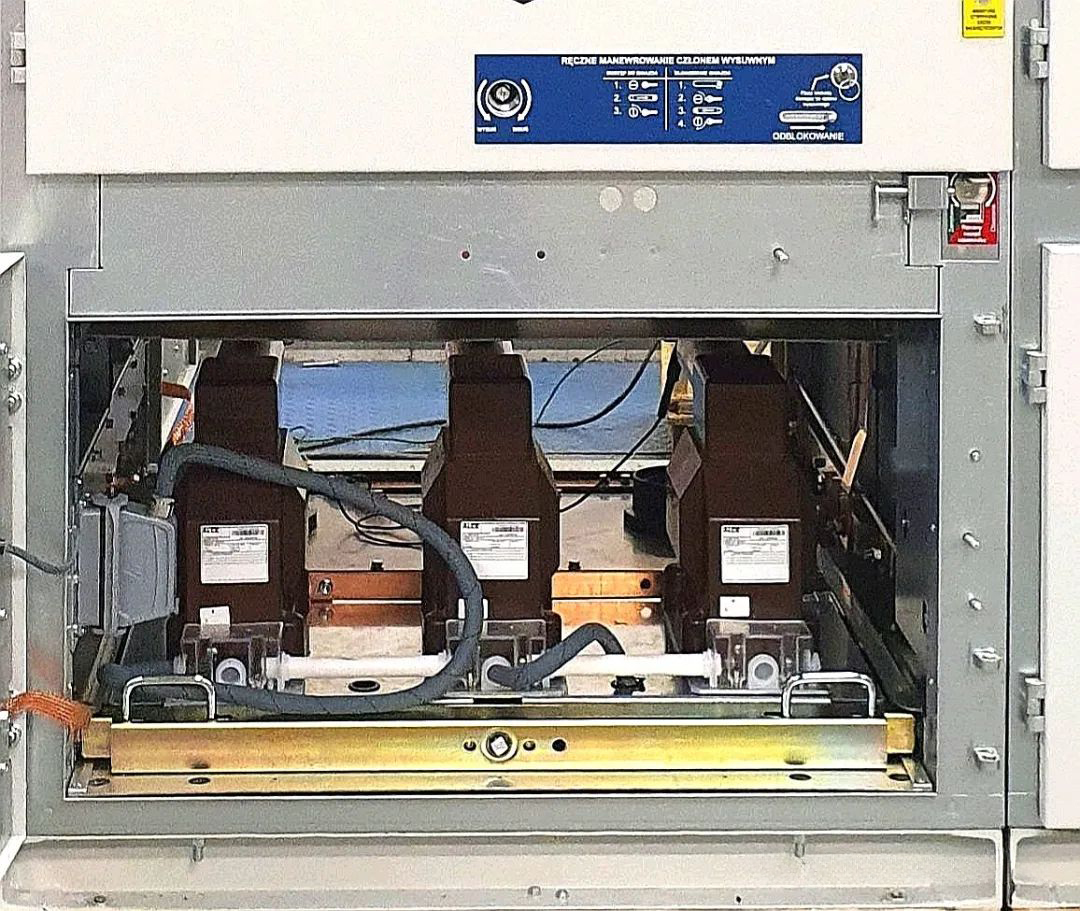

In gas-insulated switchgear, fixed-mounted circuit breakers require disconnectors for circuit isolation. For withdrawable or removable circuit breakers, the primary contacts of the movable truck function as disconnectors, providing isolation.

Earthing Switch

An earthing switch is specifically designed to short-circuit and earth the three-phase conductors. It is typically closed only during maintenance to ensure safety for personnel working on the circuit, as it grounds the de-energized live conductors.

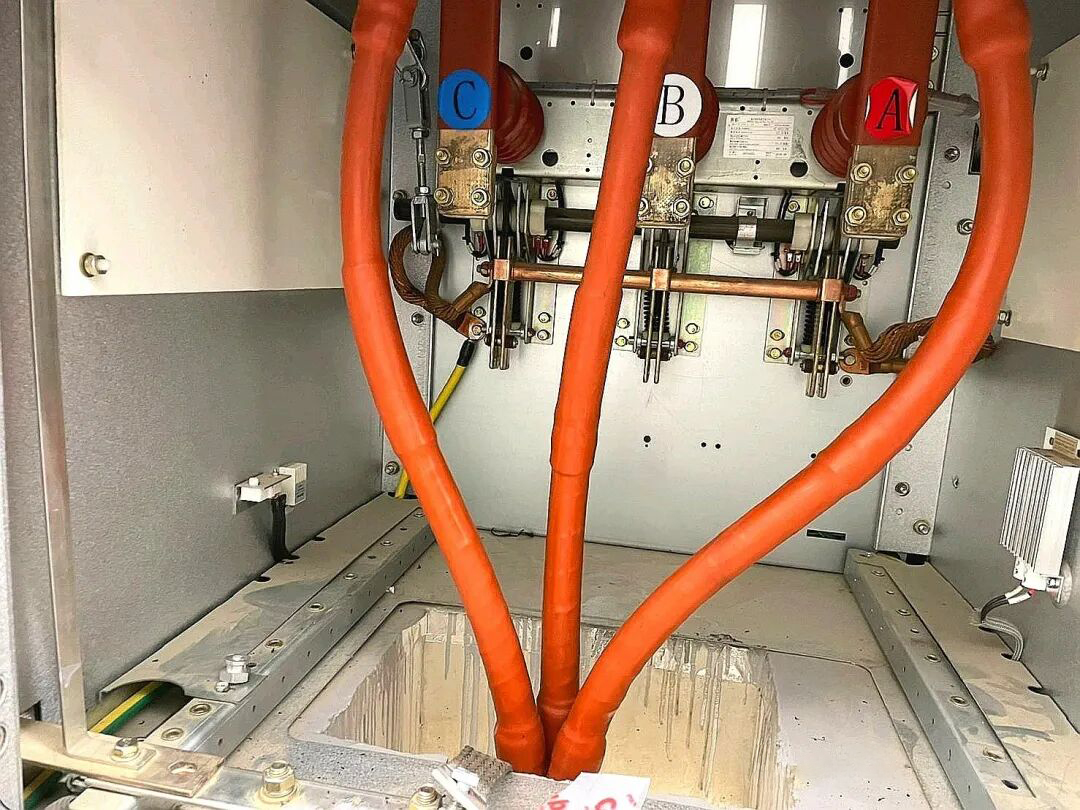

In gas-insulated switchgear, earthing switches are used to ground circuits requiring maintenance, ensuring safe. They are installed at appropriate locations, such as on the cable side or busbar side, to ground specific sections during maintenance. For example, when installed below the cable connection point in the cable compartment of the switchgear, with the circuit breaker truck withdrawn to create an isolation gap, closing the earthing switch allows safe maintenance of the cable compartment equipment, connected cables, and downstream devices without the risk of high-voltage hazards.

Load Switch

A load switch is a mechanical switching device capable of making, carrying, and breaking currents under normal circuit conditions, including overload currents during operation. It is used to control circuits (opening and closing) and often provides isolation functions. In public and private medium-voltage distribution networks, it is frequently used in combination with fuses.

Contactor

A contactor is a mechanically operated switching device with a single rest position, designed for non-manual control. It can make, carry, and break currents under normal circuit conditions, including operating voltage conditions. It is suitable for frequent functional operations and is primarily used for motor control. When used with fuses, it provides short-circuit protection.

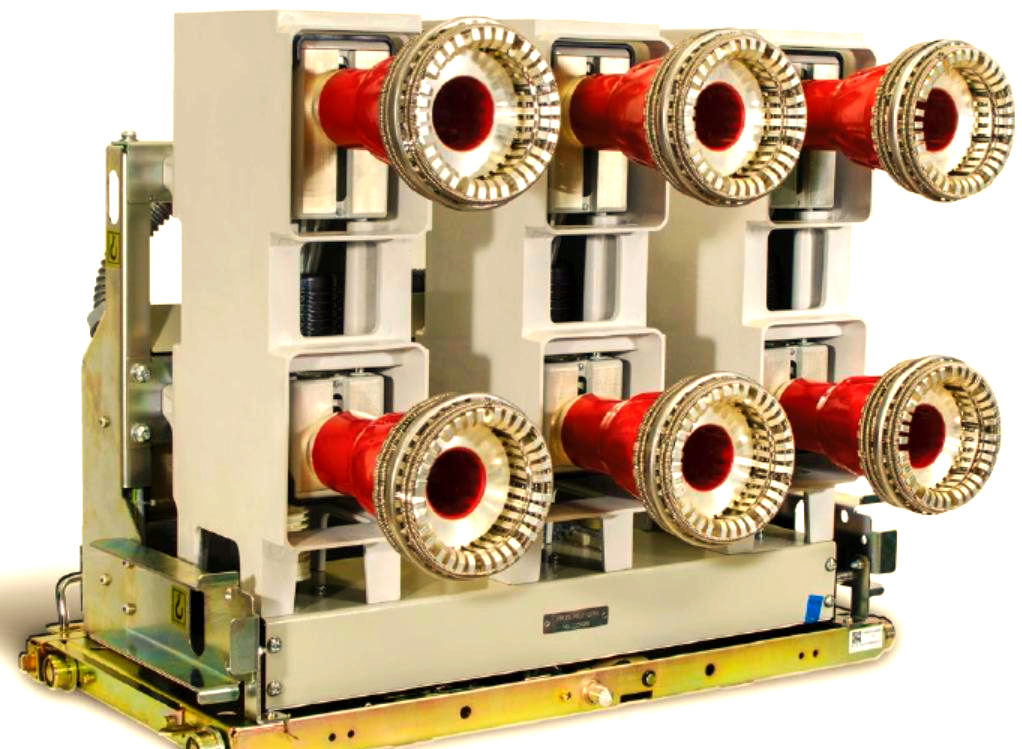

Circuit Breaker

A circuit breaker is a mechanical switching device capable of making, carrying, and breaking currents under normal circuit conditions and specific abnormal conditions (such as short circuits). It is a universal switching device that not only controls circuits but also protects them from electrical faults. It can replace contactors for controlling large medium-voltage motors.

In simple terms, under no-load conditions, all these switches can open and close normally. However, under load conditions, disconnectors and earthing switches cannot open or close, while other switches can close. Under short-circuit conditions, only circuit breakers can interrupt the fault current, while load switches, earthing switches, contactors, and circuit breakers can withstand making operations.

Besides switches, measuring voltage and current is essential. For medium voltages such as 12kV, insulated electromagnetic induction transformers are used to step down high voltages to low voltages suitable for instruments and protection devices, and to reduce large currents to small currents.

Current and Voltage Transformers

These are used for metering and protection. For example, during a short circuit, the current increases instantaneously. The current transformer detects this change and sends a signal to the protection relay, which then triggers the circuit breaker to trip. Similarly, voltage abnormalities are handled accordingly.

The above devices are installed within the metal-enclosed switchgear cabinet. The internal space is divided into grounded metal compartments for different functions, such as:

Busbar compartment for main busbar connections;

Truck compartment for circuit breakers or other switching devices;

Cable compartment for external cable connections;

Instrument compartment for control and protection devices.

Additionally, based on their applications, switchgear units are composed of different components. These units are arranged in switchgear panels to form systems for incoming power, voltage measurement, outgoing feeders, busbar coupling, and service transformers, among other applications.