1. Executive Summary

This proposal provides a comprehensive EPC (Engineering, Procurement, Construction) solution for a 33KV-11KV-0.4KV substation, specifically designed for steel manufacturing plants. The solution covers electrical system design, equipment selection, protection & control, automation systems, and civil works, ensuring high reliability and continuous power supply for steel production. The system adheres to international standards (IEC, IEEE) and incorporates smart monitoring and energy management for remote operation and fault diagnostics, optimizing power safety and energy efficiency.

2. Design Scheme & Execution Process

2.1 Overall System Architecture

The system adopts a three-stage voltage transformation:

First Stage: 33KV → 11KV (Main Transformer)

Second Stage: 11KV → 0.4KV (Distribution Transformer)

Third Stage: 0.4KV power distribution

2.2 Capacity Calculation & Design

Load Calculation (Based on IEC 61363)

Using Demand Factor (DF) and Coincidence Factor (CF):

Total Calculated Load = Σ (Equipment Rated Power × Demand Factor) × Coincidence Factor

Transformer Sizing (Based on IEC 60076, N-1 Redundancy Principle)

Main Transformer Capacity:

S = P / (cosφ × η) × 1.25 (Redundancy Factor)

Distribution Transformer:

Configurations: 2×100% or 3×50% redundancy

Grouped load calculation

Short-Circuit Current Calculation (IEC 60909 Standard)

Three-phase fault current analysis to verify breaking capacity of equipment

2.3 Execution Workflow

Pre-Engineering Phase: Site survey, load analysis, grid data collection

Design Phase: System design, protection coordination, layout planning

Procurement Phase: International tendering, factory acceptance tests (FAT)

Construction Phase: Civil works, equipment installation, cable laying

Commissioning Phase: Individual tests, system integration, protection relay testing

Operation Phase: Energization tests, performance verification, handover

3. Equipment List & System Components

3.1 Primary Equipment System

33KV Switchgear (IEC 62271 Standard)

GIS (Gas-Insulated Switchgear): SF6 insulation, including:

Circuit Breaker (CB)

Disconnector (DS)

Earthing Switch (ES)

Current Transformer (CT)

Voltage Transformer (VT)

Function: 33KV incoming protection, metering, and distribution

Power Transformers (IEC 60076 Standard)

33/11KV Main Transformer: Oil-immersed or dry-type, ONAN/ONAF cooling, with OLTC (On-Load Tap Changer)

11/0.4KV Distribution Transformer: Dry-type, natural cooling

Function: Voltage transformation & power transmission

11KV Switchgear (IEC 62271 Standard)

AIS (Air-Insulated Switchgear) with vacuum circuit breakers (VCB)

Includes: Feeder panels, bus coupler, PT panels

Function: 11KV power distribution & protection

0.4KV LV Distribution System (IEC 61439 Standard)

ACB (Air Circuit Breaker), MCCB (Molded Case CB), capacitor banks, distribution boards

Function: Final distribution & power quality control

3.2 Secondary & Automation Systems

Protection & Control System

Microprocessor-based relays (overcurrent, differential, earth fault)

IEC 61850 communication protocol

Function: Fast fault isolation & system protection

SCADA System

HMI (Human-Machine Interface)

Data acquisition servers

Historical database

Function: Real-time monitoring & data management

Power Quality System

Harmonic analyzer (IEC 61000-4-30)

Reactive compensation (SVG/capacitor banks)

Function: Ensures power quality compliance

Auxiliary Systems

220VDC system

UPS (Uninterruptible Power Supply)

Environmental monitoring (temperature, humidity, SF6 detection)

Function: Ensures control power reliability

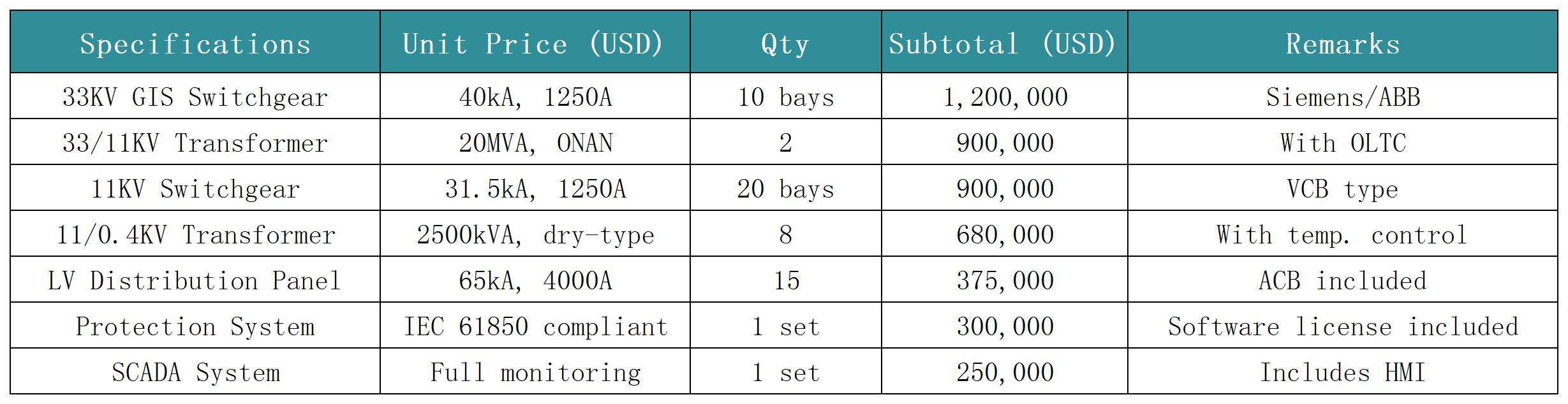

4. Equipment Cost Breakdown

4.1 Major Equipment Costs

4.2 Additional Costs

Engineering Design: ~8-10% of equipment cost (~$400,000)

Installation & Commissioning: ~15-20% of equipment cost (~$800,000)

Civil Works: ~$500,000 (foundation, cable trenches)

Project Management: ~5% of total cost (~$250,000)

Total Estimated Cost: $6M–$7M (varies based on configuration)

5. Detailed Execution Steps

5.1 Engineering Phase (8–12 Weeks)

Basic Design:

Grid parameter collection (short-circuit level, earthing method)

Load survey & classification (IEC 60364)

Single-line diagram finalization (single bus sectioned/double bus)

Detailed Design:

Electrical calculations (short-circuit, protection coordination, cable sizing)

Layout design (floor plan, elevation drawings)

Protection logic & control schematics

Design Review:

Internal 3-level verification

Client approval meeting

Utility approval (if required)

5.2 Procurement Phase (12–16 Weeks)

1).Tendering & Procurement:

Technical specifications (IEC-based)

International bidding (EU/Japanese brands preferred)

Technical agreement negotiation

2).Factory Inspection:

Witness testing (e.g., transformer FAT)

Progress tracking

Packaging & transport approval

5.3 Construction Phase (16–20 Weeks)

1)Civil Works:

Substation foundation

Cable trench construction

Earthing grid (<0.5Ω resistance)

2)Equipment Installation:

Transformer positioning (oil processing)

Switchgear assembly

Busbar connection (torque-controlled)

3)Cabling Works:

HV cable laying & termination (IEC 60502)

Control wiring

Fiber optic splicing & testing

5.4 Commissioning Phase (6–8 Weeks)

1)Individual Tests:

CB mechanical tests

Relay calibration

CT magnetization tests

2)System Integration:

Protection coordination tests

SCADA point-to-point verification

Synchronization check

3)Energization Tests:

24-hour no-load run

Load testing (phase verification)

Power quality measurement

5.5 Handover & Training (2–4 Weeks)

1)Performance Validation:

72-hour continuous operation

100% protection accuracy verification

Energy efficiency check

2)Documentation Delivery:

As-built drawings

O&M manuals

Test reports

3)Training Program:

System operation

Preventive maintenance

Troubleshooting drills

Total Project Duration: 12–18 months (varies based on complexity).

Critical Path: Equipment procurement & civil works.

This EPC solution ensures seamless execution from design to commissioning, complying with international standards (IEC/IEEE) for steel plant substations.