Scope of Application:Capacitor Bank Switchgear is designed for the safe switching, protection, and control of low-voltage (LV) and medium-voltage (MV) capacitor banks in industrial, commercial, and utility power systems. It ensures efficient reactive power compensation (RPC) to improve power factor, reduce energy losses, and enhance grid stability in compliance with IEC 60831, IEC 62271, and IEEE 18 standards.

Rated Voltage (IEC 60038): LV Systems: 400V, 480V, 690V (50/60Hz);HV Systems: 6.6kV, 11kV, 22kV, 33kV

Rated Current: 100A – 4000A (based on capacitor bank size)

Short-Circuit Withstand (IEC 62271): 25kA, 31.5kA, 50kA (1s or 3s)

Switching Duty:Back-to-back capacitor switching (IEC 62271-103); Inrush current limitation (<20× rated current)

Protection Class (IEC 60529): IP3X (indoor), IP54 (outdoor)

Product Overview (Detailed Description)

Capacitor bank switchgear represents a critical component in modern power systems, specifically engineered to handle the unique challenges associated with capacitor bank operation. These specialized switchgear assemblies integrate several key components to ensure safe and reliable performance:

The primary switching device varies according to voltage level – vacuum contactors are typically employed for LV applications (400V-690V) while vacuum circuit breakers or SF6 interrupters are standard for MV systems (3.3kV-33kV). These switching devices are specifically rated for capacitor switching duty (AC-6b per IEC 60947 for contactors, back-to-back switching per IEC 62271-100 for breakers).

A critical design consideration is the mitigation of transient phenomena during switching operations. The switchgear incorporates pre-insertion resistors or reactors to limit inrush currents to less than 20 times rated current, protecting both the capacitors and the switching device. For de-energized conditions, automatic discharge devices ensure capacitors discharge to less than 50V within 3 minutes as required by IEC 60831.

The protection system features microprocessor-based relays providing multiple protection functions including:

Overcurrent protection (50/51) with definite and inverse time characteristics

Overvoltage protection (59) with adjustable settings

Unbalance protection (46) for detecting failed capacitor elements

Thermal overload protection based on IEC 60255 standards

The enclosure design follows IEC 62271-200 requirements for metal-enclosed switchgear, with options for indoor (IP3X) or outdoor (IP54) installations. The withdrawable design facilitates easy maintenance while maintaining proper compartmentalization per IEC standards.

Control and monitoring capabilities include:

Local HMI with capacitor bank status indication

Remote control via SCADA systems

Communication interfaces supporting IEC 61850, Modbus RTU/TCP, Profibus

Real-time measurement of electrical parameters (kVAR, PF, THD%)

2.Product Functions (Detailed Description)

1).Switching Functionality

The switchgear provides reliable making and breaking of capacitor bank circuits under all normal and specified abnormal conditions. Special attention is given to:

Energization Control: Controlled closing technology minimizes transient overcurrents through:

Point-on-wave switching

Pre-insertion resistors (typically 500-1000Ω for 3-5ms)

Current-limiting reactors

De-energization: Proper arc interruption without restrikes (certified per IEC 62271-100)

2).Protection Functions

Overcurrent Protection (50/51):

Instantaneous element (50) set at 10-15× rated current

Time-delayed element (51) with IEC normal inverse curve

Overvoltage Protection (59):

Adjustable setpoint (typically 110% of Un)

Time delay to avoid nuisance tripping

Unbalance Protection (46):

Neutral voltage displacement (for ungrounded banks)

Current differential (for grounded banks)

Thermal Protection (49):

Capacitor temperature monitoring

Ambient temperature compensation

3).Control & Monitoring

Automatic Control:

Step control logic for multiple capacitor banks

Programmable time delays between switching operations

Measurement Capabilities:

True RMS voltage/current measurement

Power factor calculation

Harmonics measurement up to 25th order

Communication:

IEC 61850-8-1 GOOSE messaging

Modbus RTU over RS485

Ethernet TCP/IP for SCADA integration

4. Product Features (Detailed Advantages)

1) Enhanced Safety Features

Arc-Resistant Design: Tested per IEC 62271-200 for internal arc containment

Fast Discharge System: Meets IEC 60831 discharge requirements

Interlocking Systems: Mechanical and electrical interlocks prevent unsafe operations

2) Advanced Switching Technology

Vacuum Interruption: Maintenance-free operation with high dielectric strength

Synchronized Switching: Reduces transient overvoltages during operation

Condition Monitoring: Contact wear, operation counters, temperature monitoring

3) Smart Grid Compatibility

IEC 61850 Compliance: Supports process bus and station bus communication

Cyber Security: IEC 62351 compliant security features

Predictive Maintenance: Advanced analytics for condition-based maintenance

4) Modular & Flexible Design

Expandable Architecture: Additional capacitor steps can be added

Multiple Busbar Options: Single or double busbar configurations

Retrofit Capability: Can replace existing switchgear with minimal modifications

5) Environmental Considerations

Green Design: SF6-free alternatives available

Low Losses: High efficiency switching devices reduce energy consumption

Recyclable Materials: >90% of materials are recyclable

Conclusion

Modern capacitor bank switchgear combines advanced switching technology, comprehensive protection features and smart grid capabilities to provide reliable reactive power compensation solutions. Designed and tested to international standards, these systems ensure safe operation while optimizing power factor and improving energy efficiency in electrical networks. The integration of digital monitoring and control capabilities makes them ideal for both conventional and smart grid applications.

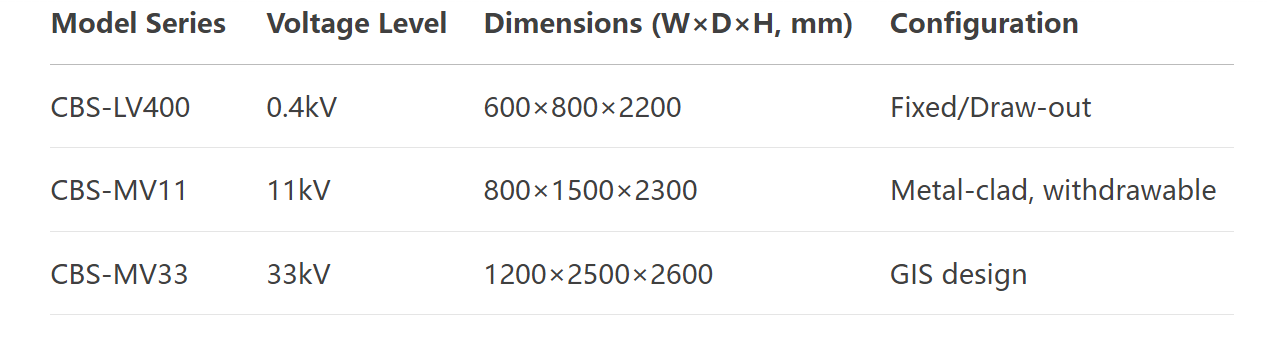

Switchgear Models & Dimensions