Transformer Protection Relay Panel is primarily used in automation systems for substations and distribution stations in power systems of 11kV, 33kV, 132kV and above. Its main function is to ensure that the transformer can promptly trip the faulty circuit in case of overload, short circuit, gas relay activation, and other abnormal operating conditions, thereby protecting the main transformer from damage and preventing the expansion of faults.

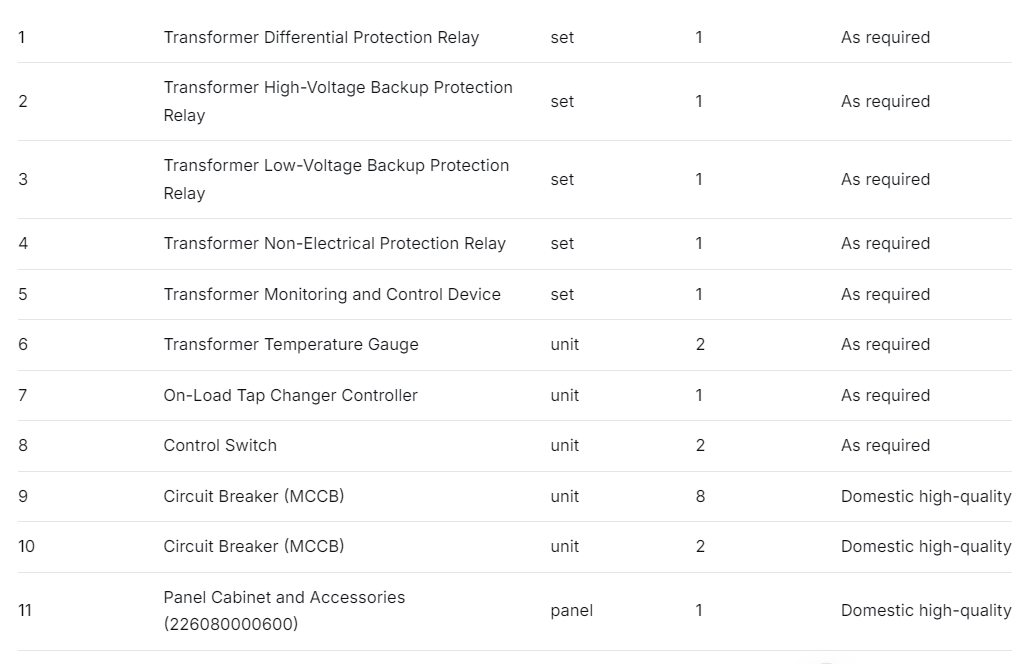

Configuration of Transformer Protection Relay Panel

The above table shows the typical configuration of a Transformer Protection Relay Panel. The core functions of the key components are detailed as follows:

Function of Transformer Protection Relay Panel

1.Transformer Differential Protection Relay: This device provides primary protection for internal transformer faults. Its main functions include percentage differential protection and differential quick-break protection. It operates in response to internal faults such as inter-turn short circuits and phase-to-phase short circuits.

2.Transformer High-Voltage Backup Protection Relay: This relay provides backup protection for the high-voltage side of the transformer and its associated downstream system. Common protection functions include three-stage overcurrent protection, zero-sequence current protection, and voltage-restrained overcurrent protection.

3.Transformer Low-Voltage Backup Protection Relay: This relay provides backup protection for the low-voltage side of the transformer and its associated downstream system. Common protection functions include three-stage overcurrent protection, zero-sequence current protection, and overload protection. Together with the high-voltage backup protection relay, it forms the complete backup protection system for the transformer, which operates if the primary protection fails.

4.Transformer Non-Electrical Protection Relay: This device protects against abnormal mechanical and thermal conditions, such as those detected by the gas relay (Buchholz relay), temperature sensors, and pressure relief devices. It rapidly isolates the transformer in cases of gas accumulation, excessively high or low oil temperature, or sudden pressure increases to prevent further damage.

5.Transformer Monitoring and Control Device: This unit is responsible for monitoring operational data (e.g., currents, voltages, power) and executing control commands, such as opening and closing the transformer’s circuit breakers.