Scope of Application

The Generator Protection Relay Panel is mainly suitable for the control and protection of hydraulic units, gas-fired units, biogas units, and large diesel units.

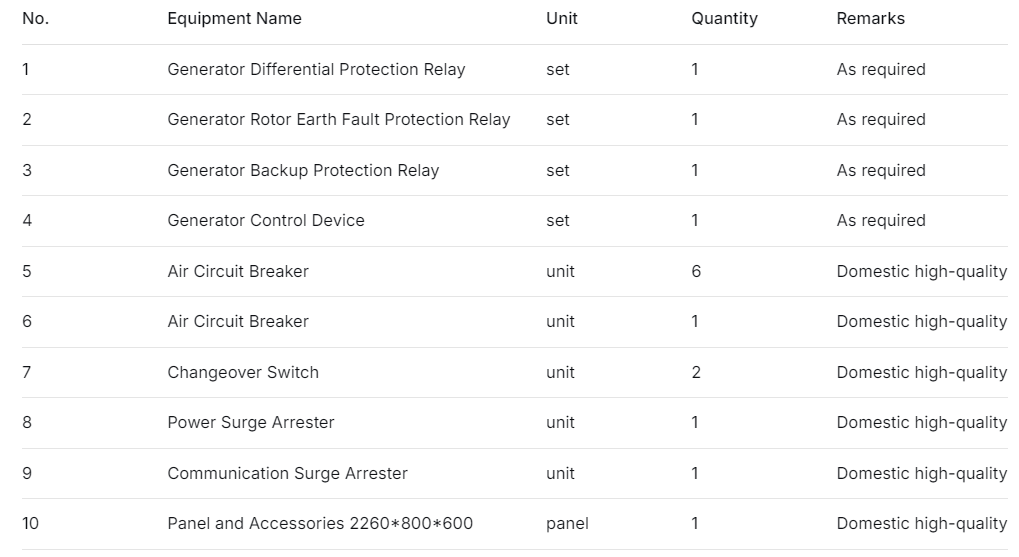

Main Components

Generator differential protection relay, generator rotor earth fault protection relay, generator backup protection relay, generator measurement and control device, cabinet (2260*800*600 or 2360*800*600) and accessories.

Integrating protection, measurement, and communication, the Generator Protection Relay Panel can realize the protection and control of various units, enabling unattended or minimally attended operation. It can achieve generator differential protection, rotor earth fault protection, stator earth fault protection, excitation protection, overcurrent protection, overvoltage protection, overload protection, backup protection, etc.

Configuration List of Generator Protection Relay Panel

Detailed Functions

1.Generator Differential Protection: Mainly protects against internal faults of the generator. It acts when phase-to-phase short circuits or turn-to-turn short circuits occur inside the generator.

2.Generator Backup Protection: Mainly protects areas outside the generator. Common protection functions include three-stage current protection, negative sequence overcurrent tripping, loss of excitation protection, loss of excitation tripping, stator earth fault zero current protection, stator earth fault zero voltage protection, stator earth fault dual-frequency protection, stator earth fault tripping, reverse power protection, underfrequency protection, etc.

3.Generator Rotor Earth Fault Protection: Divided into single-point earthing and two-point earthing of the generator rotor. Single-point earthing usually triggers an alarm, while two-point earthing requires tripping to disconnect the generator from the power grid.

Features

1.The cabinet adopts a size of 2260 (or 2360) × 800 × 600. Each cabinet can be equipped with 3 layers of devices, with 3 devices per layer. Various Protection Relays, as well as automatic control devices, are physically and spatially distributed to the primary equipment bay layer of the main substation. Each device operates as a complete system with an independent power supply, CPU, and independent operating circuit to complete protection, measurement, control, and other functions for the corresponding bay of the power station. All devices are fully independent in software and hardware design and do not rely on the communication network.

2.The CPU chip of the measurement and control device adopts an internationally advanced DSP chip. Multiple software and hardware measures are adopted, such as isolation, software and hardware filtering, watchdog circuit, anti-interference coding, intelligent diagnosis, various opening and closing control circuits, and a new anti-vibration and anti-interference structural design, which improves the reliability of the device.

3.In the communication system, each device can be directly connected to a computer for communication through a field bus, or communicate with a communication management machine. The collected various information is uploaded to the computer monitoring system through the communication management machine; at the same time, the communication management machine transmits the received various commands to the corresponding devices. The control equipment layer takes the primary equipment in the station as the measurement and control object, adopts an object-oriented approach, comprehensively analyzes the requirements of the substation for information collection, processing, and control, and distributes and configures miniaturized and high-reliability microcomputer protection and measurement and control devices. Each device is relatively independent and can communicate with substation-level equipment to realize comprehensive automation of the substation.

4.The protection panel is designed to protect not only the generator but also the excitation transformer, ensuring the reliable and stable operation of the unit, greatly reducing the probability of generator burnout, and providing a strong guarantee for long-term safe operation.

5.The protection panel is equipped with multiple communication and GPS time synchronization ports, all of which are led to terminals, facilitating communication with the power system background, so as to realize remote measurement, remote control, remote signaling, and remote adjustment of the generator by the power system background computer, and collect parameters such as active power, reactive power, current, voltage, frequency, power factor, and electricity consumption.