1. System Overview

The pumped storage power station integrated automation system is an intelligent management system centered around a computer monitoring system, integrating multiple functions such as protection, measurement, control, and communication. Utilizing modern computer technology, network communication technology, and automatic control technology, the system enables automated monitoring and control of the entire station’s equipment, including generating units, transformers, switchyards, and auxiliary systems, ensuring safe, reliable, and economical operation.

Key Features of the System:

Hierarchical and distributed architecture design

High reliability and redundant configuration

Support for standardized communication protocols

Comprehensive anti-misoperation functions

Intelligent diagnostics and early warning capabilities

User-friendly human-machine interface (HMI)

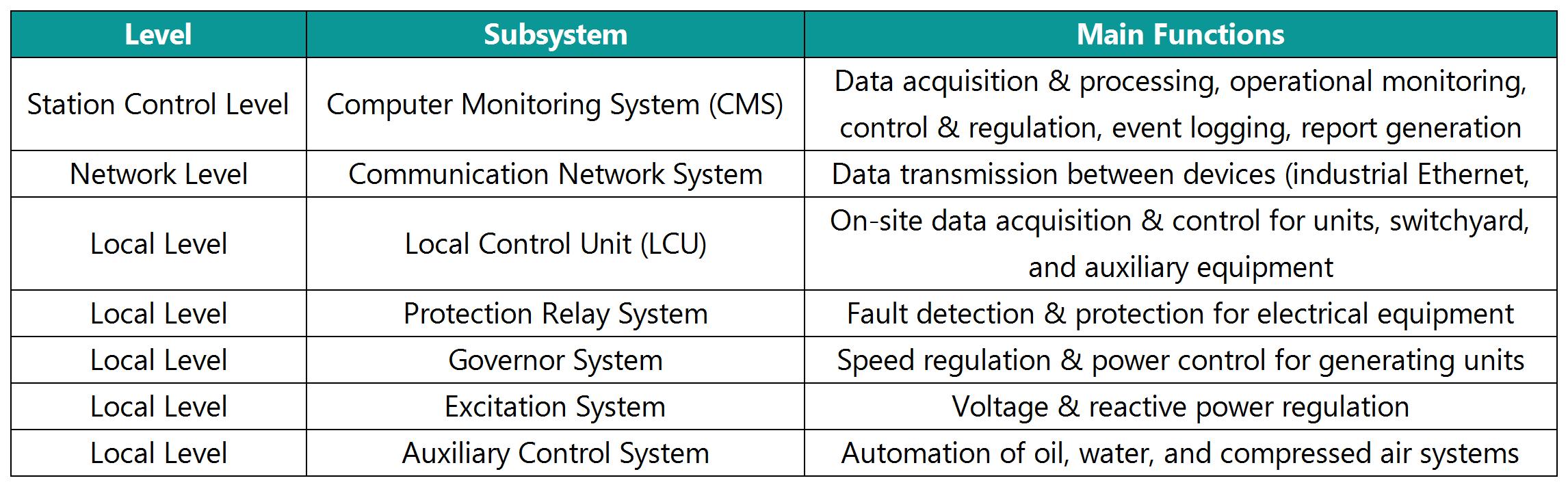

2. System Composition and Subsystem Functions

2.1 Overall System Architecture

2.2 Detailed Subsystem Descriptions

2.2.1 Computer Monitoring System (CMS)

Data Acquisition & Processing (SCADA) – Real-time collection and processing of operational parameters

Operational Monitoring – Equipment status tracking, alarm management, trend analysis

Control Operations – Unit start/stop, mode transition, load adjustment

Event Logging – System events, operation records, fault recording

Report Management – Automatic generation of operational & statistical reports

Human-Machine Interface (HMI) – Graphical operation interface & historical data query

2.2.2 Protection Relay System

Generator Protection – Differential protection, overcurrent protection, loss-of-field protection

Transformer Protection – Differential protection, Buchholz relay, overload protection

Line Protection – Distance protection, overcurrent protection, auto-reclosing

Busbar Protection – Differential protection, breaker failure protection

Station Service Protection – Overcurrent & earth fault protection

2.2.3 Local Control Unit (LCU)

Unit LCU – Start/stop control, mode transition, protection interlocking

Switchyard LCU – Circuit breaker & disconnector control, voltage/reactive power regulation

Auxiliary LCU – Control of station service systems, drainage, compressed air

Gate LCU – Intake/outlet gate control & monitoring

2.2.4 Governor System

Speed & power regulation

Frequency control

Mode transition control

Protection coordination

2.2.5 Excitation System

Generator voltage regulation

Reactive power control

Field forcing & limitation functions

De-excitation & overvoltage protection

3. System Hardware & Software Configuration

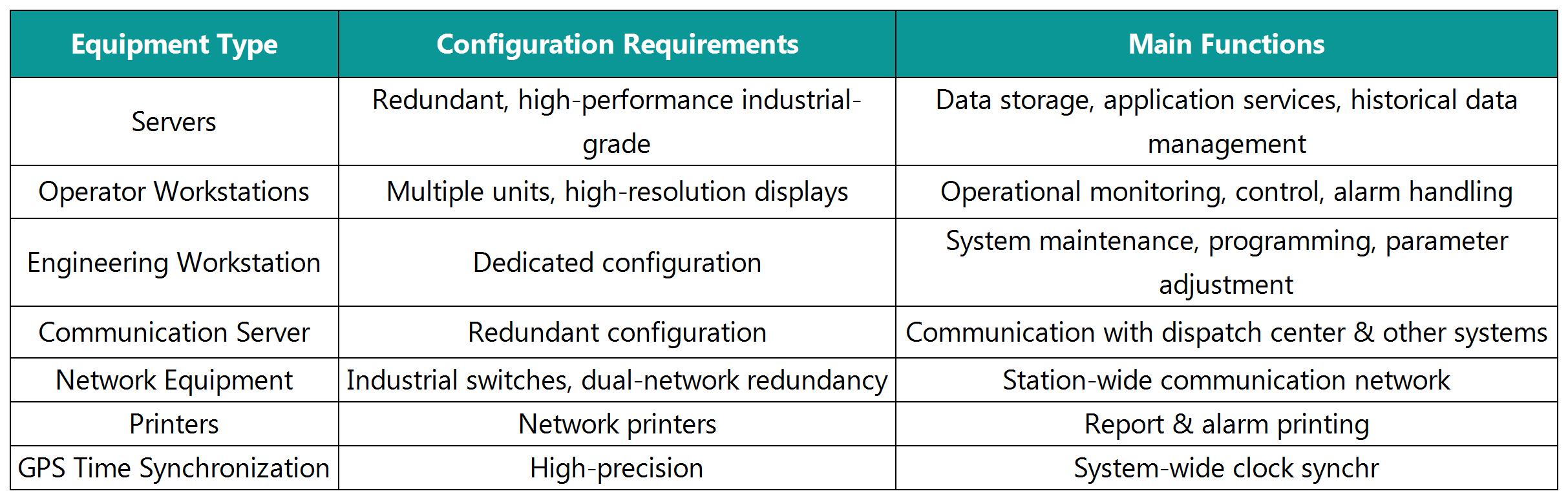

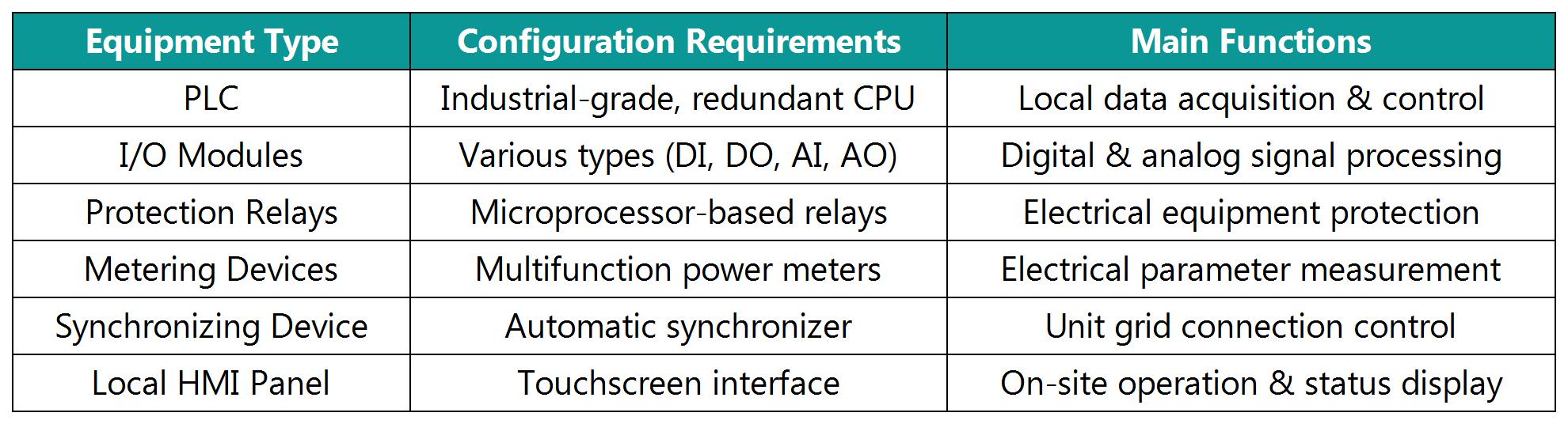

3.1 Hardware Configuration

3.1.1 Station Control Level Hardware

3.1.2 Local Level Hardware 3.2 Software Configuration

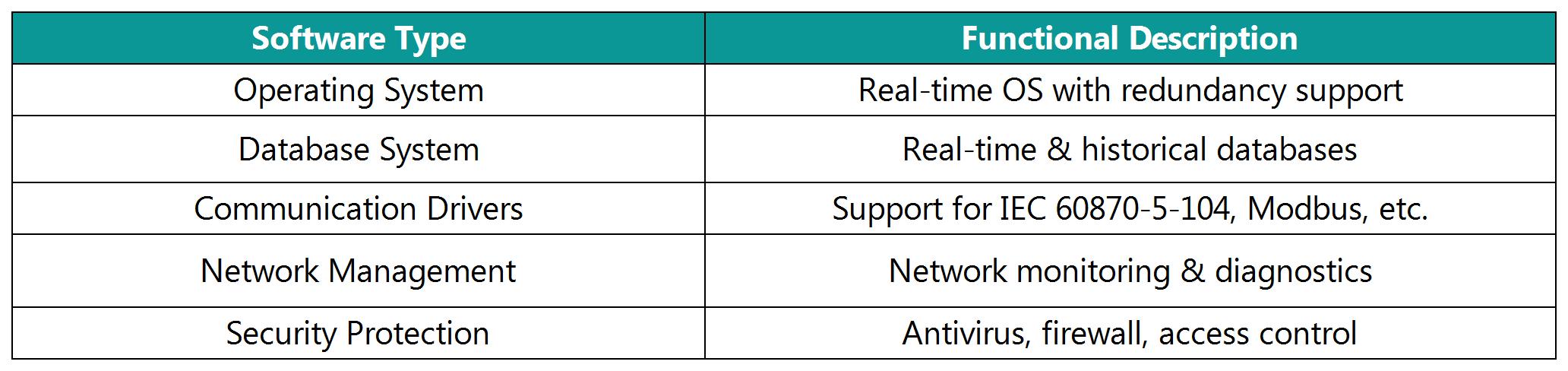

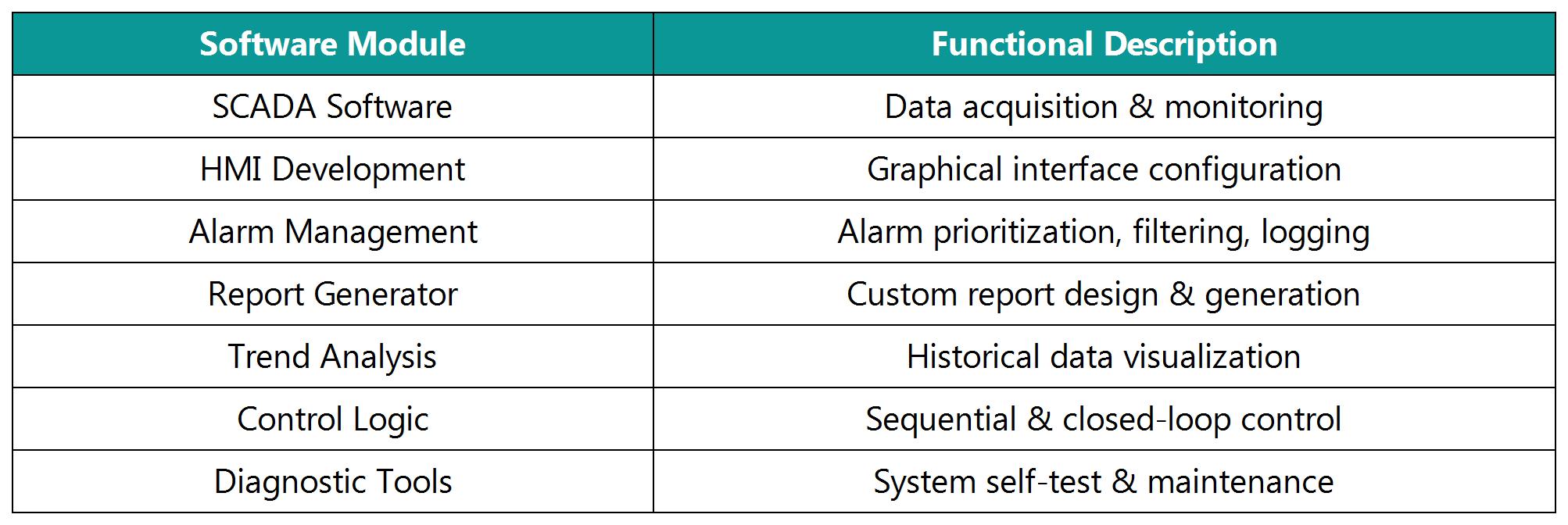

3.2 Software Configuration

3.2.1 System Software

3.2.2 Application Software

3.3 Key Equipment Technical Specifications

3.3.1 Computer Monitoring System

MTBF (Mean Time Between Failures) ≥ 50,000 hours

System Availability ≥ 99.9%

Control Command Response Time < 1 sec

Screen Refresh Time < 2 sec

Dual-Network Redundancy & Hot Standby Support

3.3.2 PLC System

Scan Cycle ≤ 10 ms

IEC 61131-3 Programming Standard Compliance

Hot-Swappable Module Support

Operating Temperature Range -20°C to 60°C

Industrial-Grade EMI Immunity (Level 4)

3.3.3 Protection Relays

Protection Operation Time ≤ 30 ms

Measurement Accuracy 0.2 class

IEC 61850 Communication Protocol Support

Fault Recording Capability

Remote Setting Adjustment & Protection Enabling/Disabling

4. Key Technical Requirements

4.1 Reliability Requirements

Redundant configuration for critical equipment

Automatic fault detection & switching

Electromagnetic interference (EMI) resistance

Anti-misoperation interlocking

4.2 Real-Time Performance Requirements

Status Change Transmission to Station Level ≤ 1 sec

Analog Value Transmission (Deadband Exceeded) ≤ 2 sec

Control Command Execution Cycle ≤ 1 sec

Adjustable Screen Refresh Rate (1–3 sec)

4.3 Security Requirements

Multi-level access control

Multi-step command confirmation

Operation logging & traceability

Cybersecurity protection measures

4.4 Scalability Requirements

Support for equipment capacity expansion

Modular functional expansion capability

Additional communication interface support

Software upgrade compatibility