1. Overview

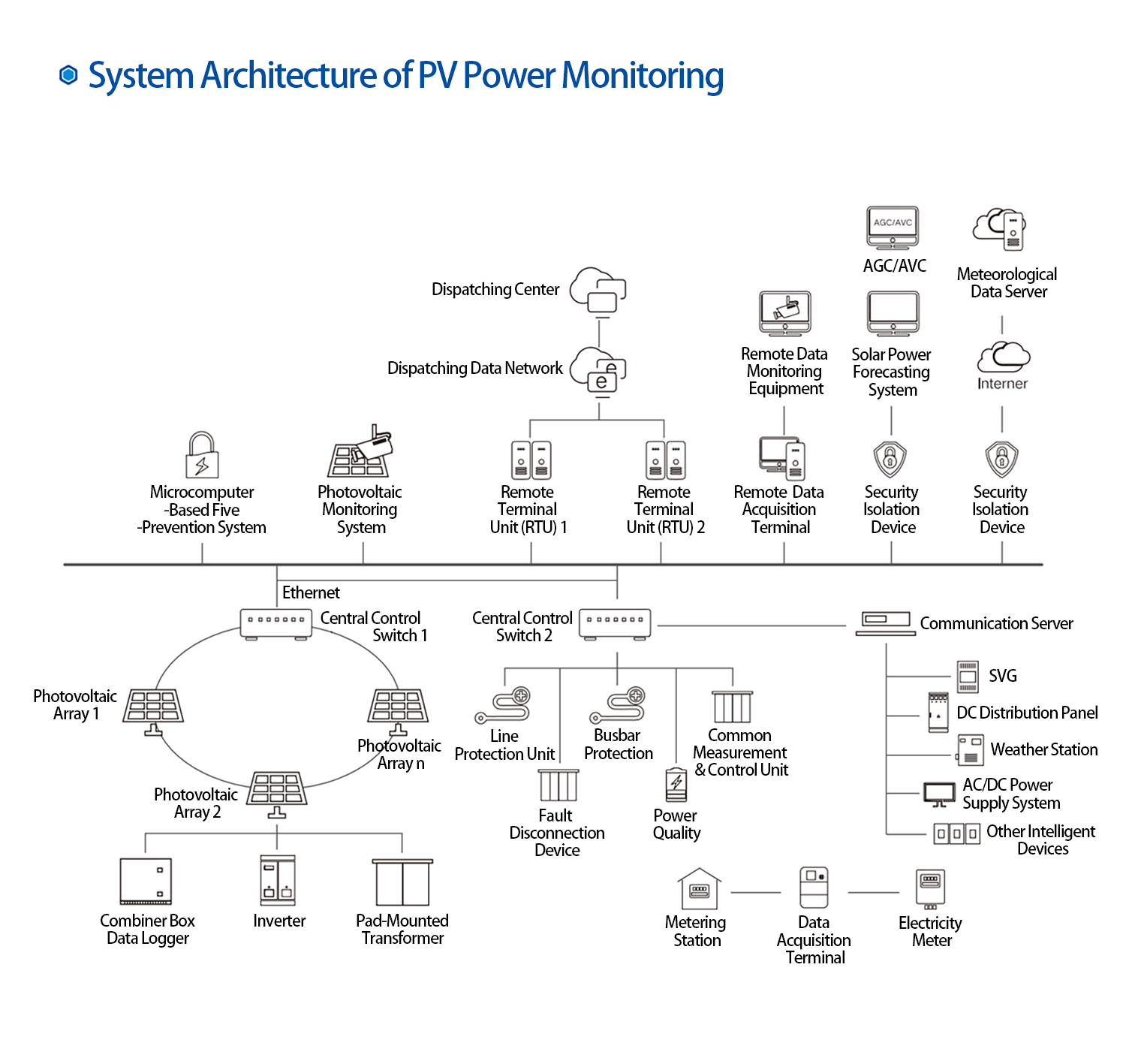

The Distributed PV Power Plant Substation Integrated Automation System is the core control system for the safe, stable, and efficient operation of grid-connected photovoltaic (PV) power generation. It integrates protection, monitoring, control, and communication functions to comprehensively manage the PV plant, ensuring power quality compliance, anti-islanding protection, rapid fault isolation, and power optimization.

The system adopts a hierarchical and distributed architecture (station control layer, bay level, and process level) and complies with IEC 61850 standards, supporting data acquisition, equipment monitoring, fault protection, and power regulation. It also meets grid dispatching automation requirements. Key objectives include:

Enhanced Reliability: Minimizes outage risks through fast fault detection and isolation.

Optimized Operation: Improves generation efficiency using AGC/AVC and solar power forecasting.

Smart Management: Enables remote monitoring, automated alarms, and data analytics to reduce O&M costs.

2. System Components

2.1 Software Components

2.1.1 PV Monitoring System Software

Functions:

Real-time monitoring of PV modules, inverters, combiner boxes, and transformers (voltage, current, power, temperature, etc.).

Data logging (energy yield, irradiance, ambient temperature) with historical analysis capabilities.

Fault alarms (inverter shutdown, string failures, communication loss) and work order management.

Performance ratio (PR) analysis and loss diagnostics for O&M optimization.

Features:

Web/APP remote access with visualization (GIS maps, trend curves, report export).

Supports Modbus, IEC 61850, DL/T 645 protocols.

2.1.2 SCADA (Supervisory Control and Data Acquisition) System

Functions:

Integrated data collection (electrical parameters, equipment status, switch positions).

Sequence of Events (SOE) recording and fault replay (PDR) for diagnostics.

Execution of dispatching commands (AGC/AVC adjustment, remote switching).

Features:

Redundant hot standby for high availability.

Compatible with OPC UA, IEC 104 for seamless grid dispatching integration.

2.2 Hardware Components

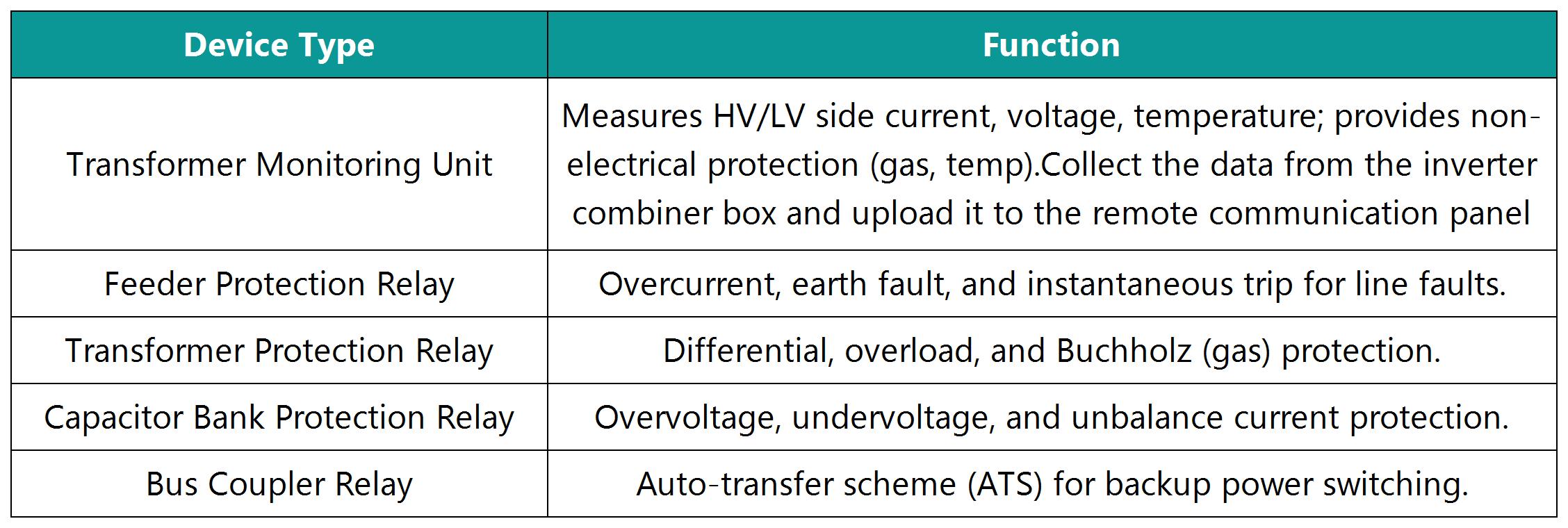

2.2.1 PV Protection Panel

Configuration:

Anti-Islanding Protection Relay: Disconnects PV from the grid upon voltage loss to prevent unintended islanding.

Fault Ride-Through (FRT) & Disconnection Unit: Ensures compliance with grid codes during faults.

Power Quality Analyzer: Monitors harmonics, flicker, and frequency deviations per IEEE 1547/UL 1741.

Purpose: Ensures grid stability and prevents PV system malfunctions from affecting the power network.

2.2.2 AGC/AVC Control Panel

Configuration:

Automatic Generation Control (AGC): Adjusts active power output based on dispatching commands.

Automatic Voltage Control (AVC): Regulates reactive power via SVG/SVC or inverter control to maintain voltage stability.

Purpose: Complies with grid operator requirements for active/reactive power management.

2.2.3 Solar Power Forecasting System Panel

Configuration:

Weather Station (irradiance, temperature, wind speed sensors).

Forecasting Server (NWP-based and machine learning algorithms).

Purpose:

Short-term (0–72h) and ultra-short-term (15min–4h) generation forecasting.

Optimizes battery storage dispatch to reduce curtailment.

2.2.4 AC/DC Power Supply Panel

Configuration:

AC Panel: Supplies station auxiliaries (lighting, HVAC).

DC Panel: Battery bank (lead-acid/lithium) + charger, providing DC 220V/110V backup.

Purpose: Ensures uninterrupted operation of protection/communication systems during grid outages (≥2h autonomy).

2.3 Communication System

2.3.1 Remote Terminal Unit (RTU) Panel

Configuration:

RTU/Protocol Gateway: Supports IEC 60870-5-104, DNP3.0, Modbus TCP.

Time Synchronization (GPS/BeiDou): Delivers IRIG-B/PTP timing for device synchronization.

Industrial Ethernet Switch: Forms a fiber-optic ring network for high availability.

Purpose: Enables SCADA telecontrol (telemetry, telecommand, telesignaling, teleadjustment) for grid dispatching.

2.3.2 Dispatching Data Network Panel

Configuration:

Longitudinal Encryption Device: Secures data transmission over the power dispatching network.

Router & Firewall: Isolates data between security zones (I/II/III) per IEC 62351.

Purpose: Connects to EMS/DMS for real-time data exchange and control command execution.

3. Key Features

Modular Design: Independent panels for easy maintenance and scalability.

High Reliability: Redundant protection and power supply systems.

Smart O&M: AI-driven fault prediction and performance optimization.

Standard Compliance: IEC 61850 for interoperability, IEEE 1547 for grid interconnection.

Cybersecurity: Encryption, role-based access control (RBAC), and network segmentation.

This system is essential for achieving unmanned operation and intelligent management in distributed PV plants, maximizing energy yield while minimizing operational costs.