Here is a detailed introduction to the integrated automation system for commercial and industrial photovoltaic energy storage power stations, including the system composition, main functions, and technical standards. Welcome to check it out! 1. System Architecture

1. System Architecture

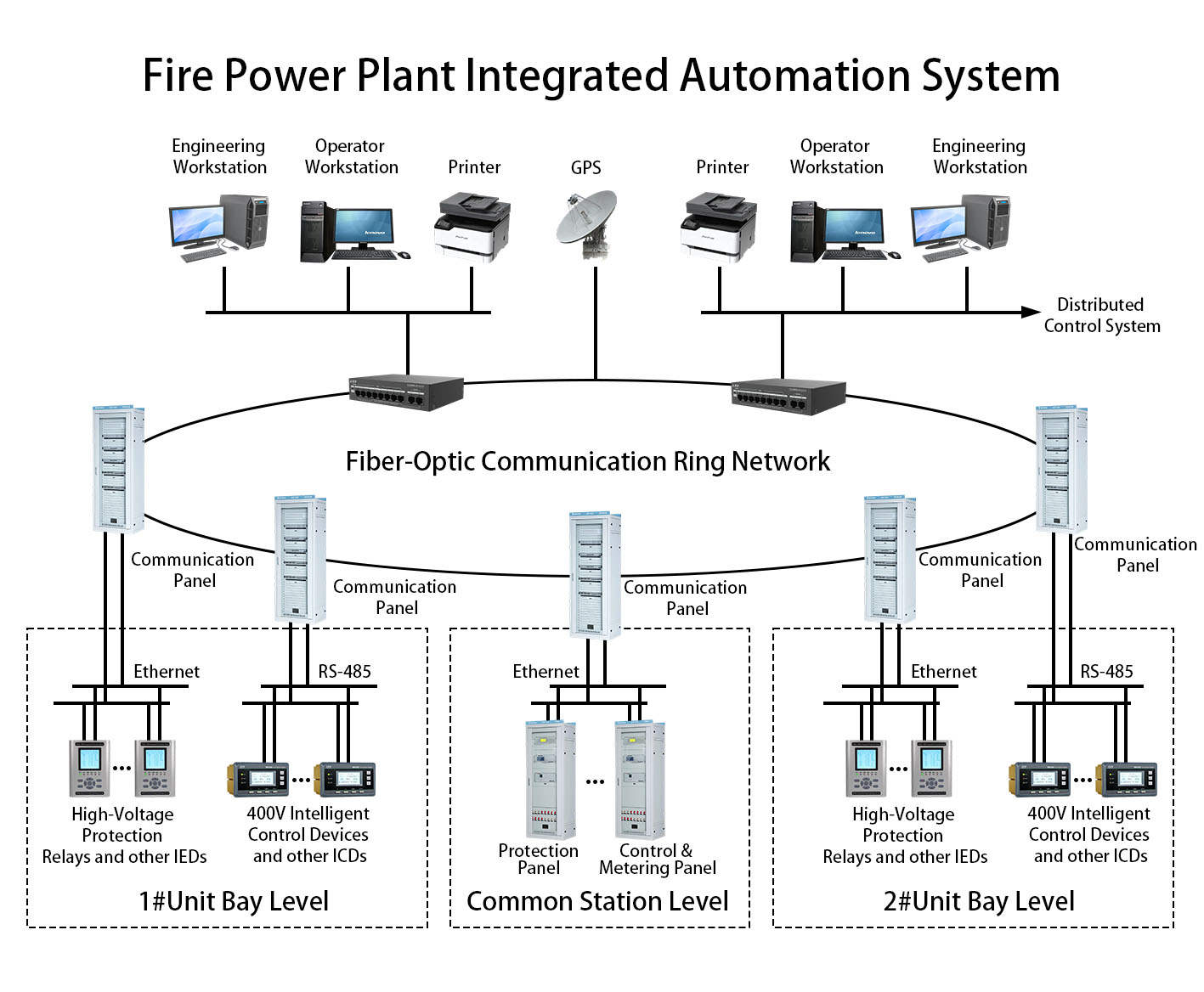

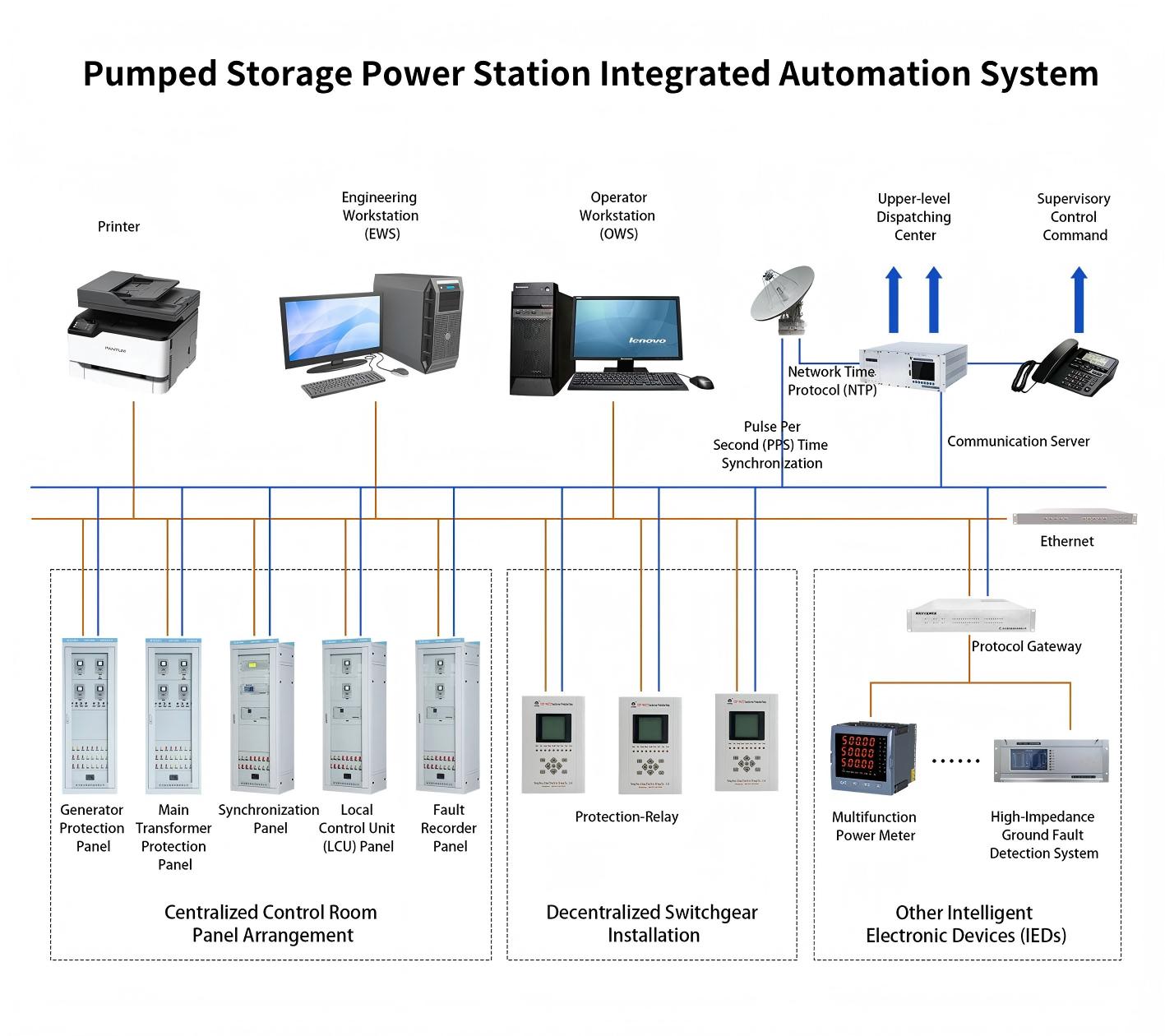

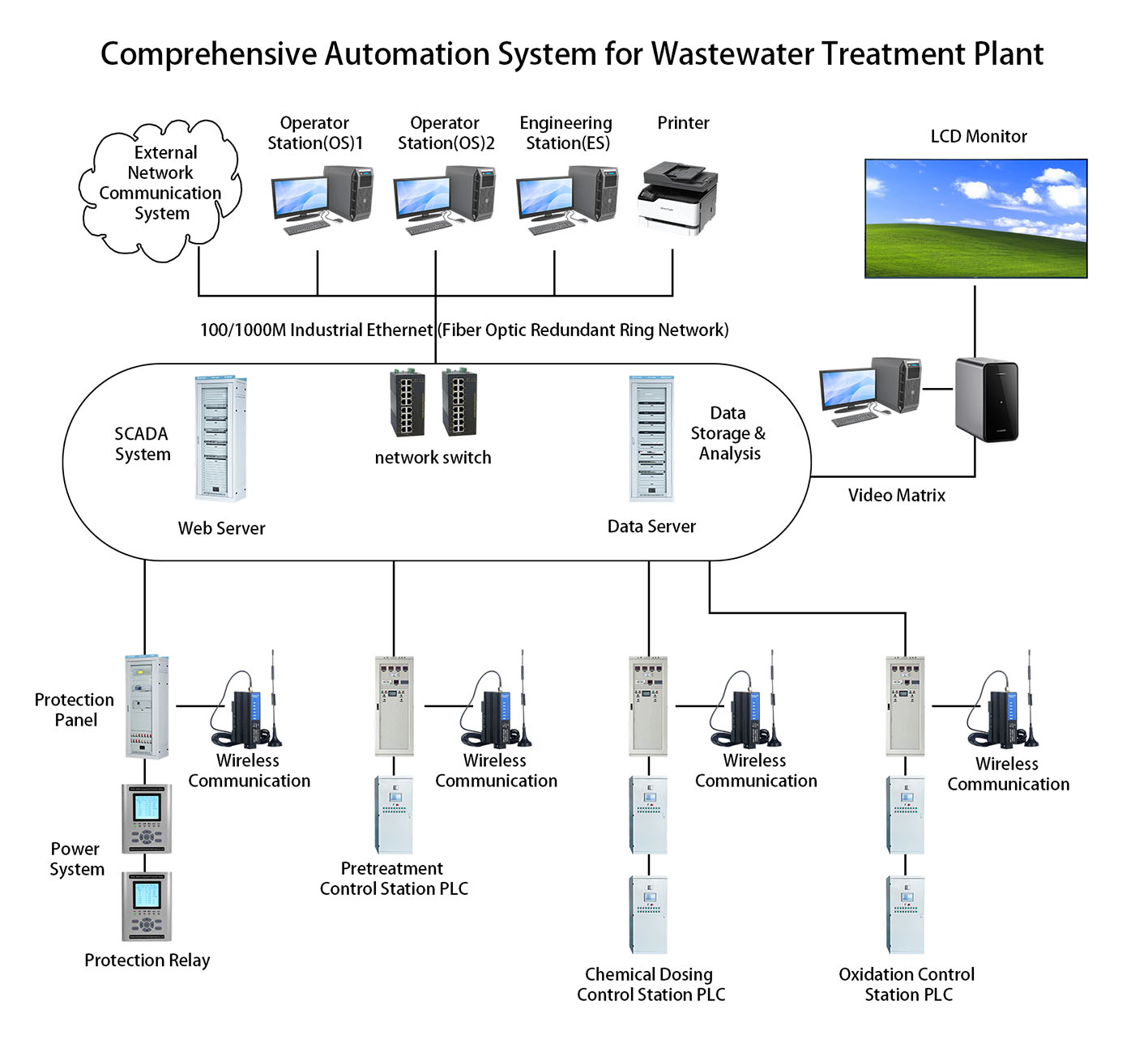

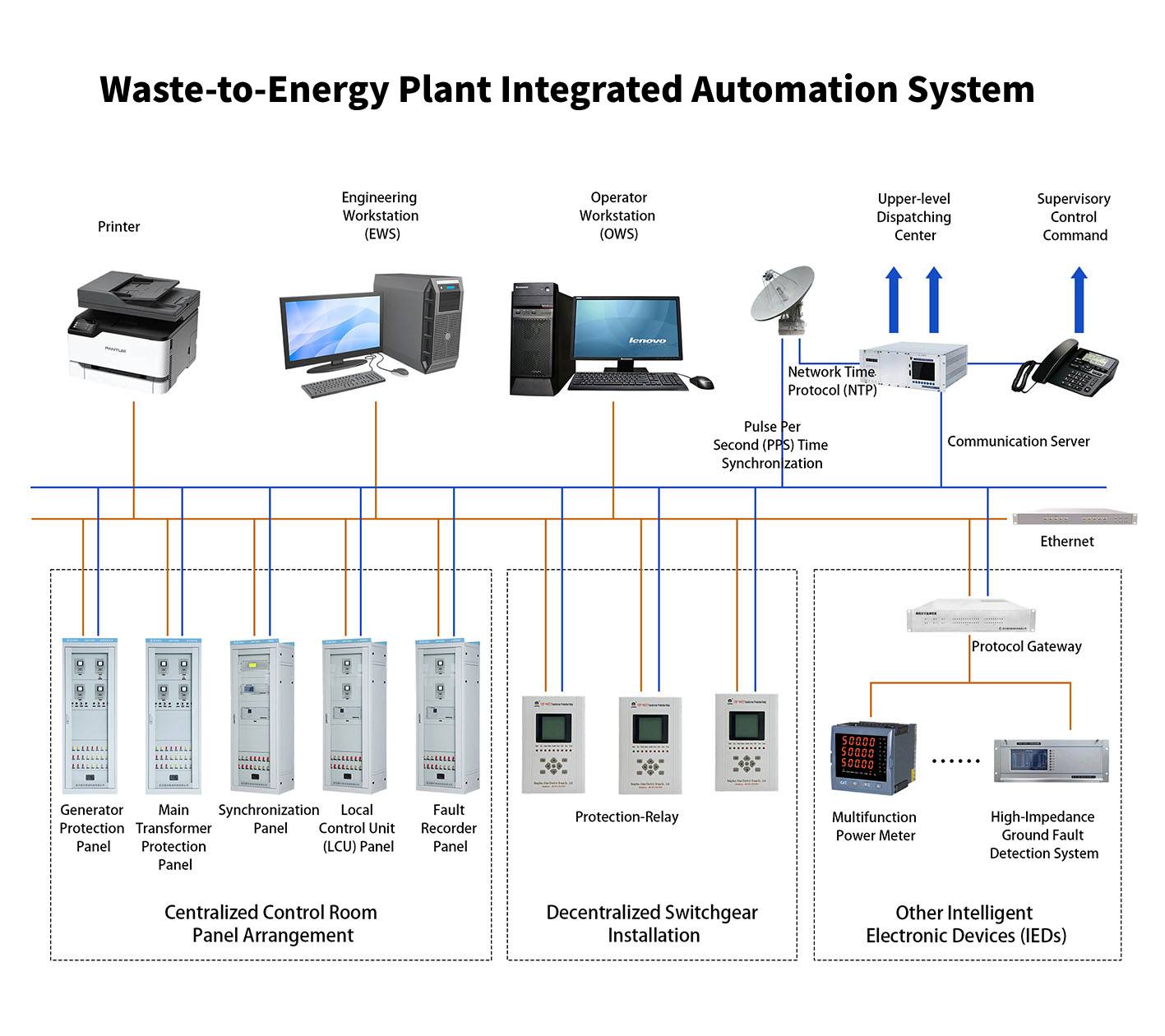

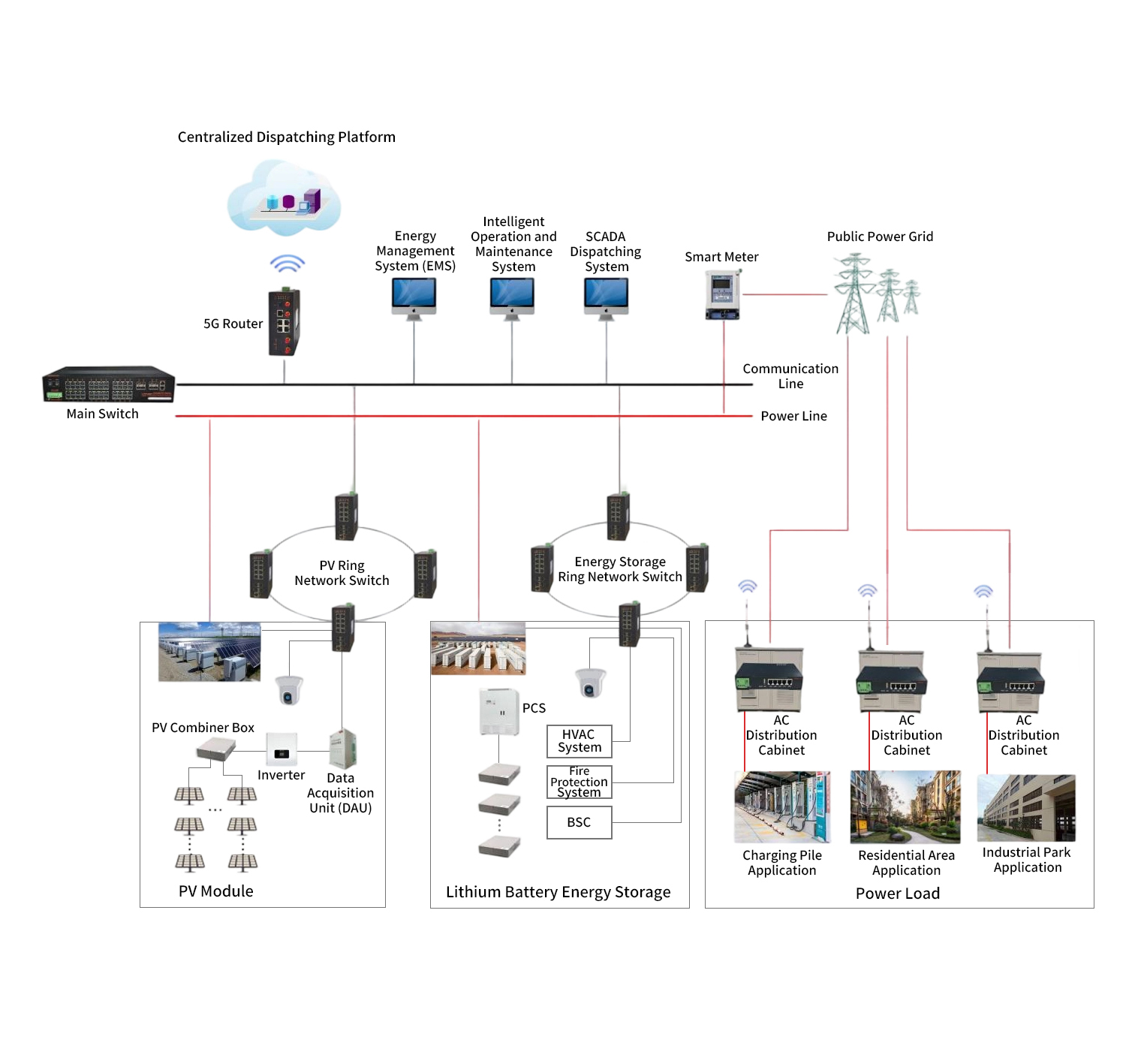

Hierarchical Design

Field Layer:PV Array, BESS (IEC 62933 compliant), Bi-directional PCS (IEEE 1547-2018), Intelligent Circuit Breakers (IEC 60947), Environmental Sensors (IEC 61724-1).

Control Layer :PLCs (IEC 61131-3), Protection Relays (IEC 60255), Power Quality Monitors (IEC 61000-4-30).

Communication Layer :Industrial Ethernet (IEC 61850-3), Fiber-optic Ring Network (redundant), Protocol Gateways (Modbus TCP/IEC 104/OPC UA).

SCADA/EMS Layer :SCADA System (IEEE C37.1), Energy Management System (EMS, IEC 62933-5).

Application Layer :Cloud Platform (ISO/IEC 27001 certified), Mobile APP, AI-based Analytics Tools.

2. Core Functions

1)Real-time Monitoring

Compliant with IEC 62443-3 cybersecurity standards:

String-level PV monitoring (IEC 61724-1).

Cell-level battery voltage/temperature monitoring (UL 1973).

2)Energy Management

IEC 62933-5 compliant EMS features:

Peak shaving & valley filling.

Demand charge management.

Frequency response (FRT per IEEE 1547-2018).

3)Safety & Protection

Electrical Protection (IEC 60255 series):

Anti-islanding (IEEE 1547).

Battery overcharge/discharge protection (UL 9540A).

4)Predictive Maintenance

Machine learning algorithms (ISO 13374-1) for equipment health analysis.

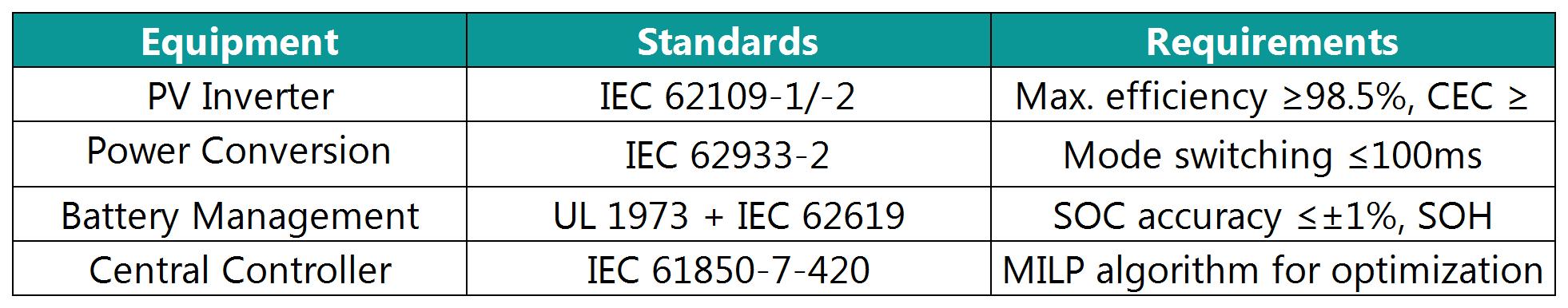

3. Key Equipment Configuration

4. Performance Indicators

Grid Compliance : Voltage/frequency response time: ≤2s (IEEE 1547-2018);THD: <3% (IEC 61000-3-6).

Energy Efficiency : Round-trip efficiency (DC-AC): ≥85% (IEC 62933-2).

Availability : Annual system availability: ≥99% (MTTR<4 hours).

5. Implementation Process

Feasibility Study : Grid compatibility analysis per IEC 63052.

Detailed Design : Single-line diagram (IEC 61082-1), Communication topology.

Commissioning & Certification : Grid integration test (IEC 62477-1); Safety certifications (UL 1741 + IEC 62109).

6. Compliance

Grid Codes: Local regulations (e.g., China GB/T 36547, US IEEE 1547).

Safety: UL 9540 (ESS safety), NFPA 855 (fire protection).

Cybersecurity: IEC 62351 (power system data security).

7. Case Study

Project: 20MWp PV + 5MW/10MWh BESS for a multinational manufacturer

Solution:

Siemens Spectrum Power EMS for coordinated control.

AI forecasting (RMSE<5%) achieving 92% self-consumption rate.

TÜV Rheinland certified (full IEC 62933 testing).

This solution strictly adheres to international standards, ensuring technical, safety, and scalability. Local adaptation per regional regulations (e.g., EU CE, US NEC) is recommended. Implementation requires Certified System Integrators (CSI).