Yarlung Tsangpo Hydropower Projects (primarily the planned Motuo station on the lower Great Bend and projects like Zangmu under construction) represent one of the world’s most challenging and strategically significant hydropower undertakings. From a technical perspective, their complexity involves several critical aspects:

1. Unparalleled Hydropower Resource Potential:

- Enormous Hydraulic Head: Traversing the Himalayas and forming the famous “Great Bend,” the Yarlung Tsangpo plunges more than 2,000 meters (potentially even 3,000 meters) over just a few hundred kilometers. This creates an exceptional natural drop for harnessing hydro energy.

- Abundant Water Volume: The Yarlung Tsangpo is China’s second-largest river by discharge volume (after the Yangtze). Its immense average annual discharge (approx. 1400 billion cubic meters, estimated at over 2000 billion cubic meters at the Great Bend) translates into staggering hydro energy potential, theoretically exceeding that of the Three Gorges by multiples.

- Concentrated Energy Potential: The massive drop concentrated within a relatively short river reach results in extremely high energy density per unit length.

2. Extreme Geological Challenges:

- Ultra-High Seismic Intensity: The Motuo area lies within the seismically hyperactive southeastern margin of the Tibetan Plateau, one of the world’s most earthquake-prone zones. Stations must withstand ultra-high seismic loads (extremely high peak ground acceleration design values), placing unprecedented seismic design requirements on dams, powerhouses, tunnels, and other structures.

- Complex Geological Structure: Situated in the intense collision zone between the Indian and Eurasian tectonic plates, the area features complex faulting, widespread structural fracture zones, and highly variable rock stress states (high in-situ stresses). Risks of rockburst are extreme. Tunnel or dam foundation excavations are prone to encountering instability in fractured, weak, squeezing, or heavily deformed rock masses, potentially including high geothermal hazards.

- Deep Incised Canyon Terrain: The steep, narrow valley presents severe slope stability issues. High, steep valley walls pose risks of collapses, landslides, and debris flows. Construction space is severely restricted.

3. Pushing the Limits of Engineering Design & Structural Technology:

- Dam Type Selection & Design: Conventional arch or gravity dam designs face extreme challenges under such complex topography and geology.

- Gravity Dams: Require extremely high foundation bearing capacity, necessitating complex ground improvement techniques (e.g., large-scale foundation replacement, deep consolidation grouting).

- Arch Dams: Offer advantages in narrow canyons but place extreme demands on the quality and stress conditions of the abutment rock. Overcoming issues like stress relaxation and deformation under high in-situ stresses presents unprecedented design difficulties.

- Embankment/CFR Dams: May be more feasible options, but still require solving critical problems like deep overburden treatment (if present), ultra-high slope stability, and deformation control under strong earthquakes. Current preference leans towards diversion tunnel schemes (like Motuo) to avoid building ultra-high dams in the steep canyons, though substantial intake structures (diversion weir/dam) are still needed.

- Massive Deep-Buried Long Tunnels: Tunnel diversion schemes are key to harnessing the Great Bend section.

- Immense Scale: Tunnels may extend dozens of kilometers, with huge diameters (potentially exceeding 10 meters), buried at extraordinary depths (over 2000 meters).

- Technical Hurdles: Rockburst under high stress, large deformation in soft rock, high geothermal temperatures (thermal hazards), high-pressure water inflows (requiring managing fault-related water conduits), ventilation, managing long-distance continuous construction logistics, and the applicability and safety risks of TBMs (Tunnel Boring Machines) in such extreme conditions (requiring bespoke ultra-strong support systems) constitute world-class challenges.

- Giant Underground Powerhouses: Capacity could reach tens of gigawatts, necessitating some of the world’s largest underground cavern complexes.

-

- Cavern Stability: Ensuring the stability of cavern groups in rock masses subject to strong earthquakes, high in-situ stresses, and complex lithology is a core difficulty. This demands meticulous excavation sequences and advanced support structures (e.g., high-strength, large-capacity prestressed rock anchors, bolt systems).

- Ventilation & Outlets: Designing ventilation systems, transport access, and high-voltage outlet systems for deep-buried, large-scale powerhouses is highly complex.

- Ultra-High Head Giant Turbine-Generator Units: Motuo’s turbines are projected to operate at heads in the range of 1000-2000 meters (far exceeding conventional designs).

-

- Materials & Strength: Turbine runners, shafts, penstocks, and valves must withstand extreme hydraulic loads, requiring materials and components pushed to their limits in terms of strength, fatigue life, cavitation resistance, and sediment abrasion resistance. This demands R&D and application of ultra-high-strength special alloy steels, novel composite materials, and advanced protective coatings.

- Design & Manufacturing: Developing models, designing prototypes, precision manufacturing, and testing of ultra-high head Francis or Pelton turbines constitute major technological bottlenecks.

- Stability & Control: Ensuring the operational stability and regulating performance of ultra-high head, ultra-large capacity units under complex grid conditions and load transients is a significant challenge.

4. Extreme Construction Environment & Technical Difficulties:

- Access and Logistics: The treacherous terrain around Motuo lacks robust infrastructure. Transporting massive construction equipment and materials for tunnels and dams is a colossal challenge, requiring major investments in dedicated roads, bridges, and potentially even partial airlift capabilities.

- Construction Safety under Geological Hazards: Earthquakes, rockbursts, large deformations, water inflows, and landslides constantly threaten worker safety. Demands include cutting-edge geological prediction techniques (TSP, ground-penetrating radar, borehole imaging), intelligent monitoring and early warning systems, and robust emergency response plans.

- High-Altitude Climate & Environment: High elevation, harsh and variable weather (torrential rain, snowstorms), and short effective construction seasons severely test human endurance and equipment reliability.

- Construction Management: Organizing vast human and material resources and coordinating activities like tunneling, powerhouse excavation, dam construction (if applicable), and equipment installation in such an extreme environment presents unprecedented management challenges.

5. Ultra-High Voltage Power Transmission Technology:

Ultra-High Voltage DC Transmission (UHVDC): The vast distance (over 2000 km) to energy demand centers (eastern China) necessitates UHVDC technology (e.g., ±1100kV level) for efficient, low-loss, high-capacity power delivery. This involves manufacturing and safely operating key equipment – converters, converter transformers, smoothing reactors, bushings, circuit breakers – at the world’s highest voltage levels. Requirements for insulation coordination and electromagnetic environment control are extreme. Integrating this power into the grid and ensuring stable operation (e.g., considering islanding scenarios, frequency stability) brings additional challenges.

6. Ecological Protection & Disaster Mitigation:

- Sensitive Ecosystem: The Yarlung Tsangpo Grand Canyon is a global biodiversity hotspot. Construction must prioritize minimizing impacts on ecosystems, endemic species, and hydrological regimes. Implementing measures like mandated ecological flow releases, fish passage facilities (extremely difficult), and habitat protection/restoration is essential. Environmental impact assessment standards are exceptionally stringent.

-

- Geological Hazard Prevention: Large reservoirs may impact slope stability, potentially triggering earthquakes (Reservoir Induced Seismicity – RIS) or intensifying landslide risks. Extensive geological surveys and assessments are needed, alongside preventative and mitigation measures.

- Fluvial Geomorphology Impacts: Damming the river and forming a large reservoir will significantly alter downstream sediment transport and flow patterns, requiring studies on long-term geomorphic and eco-hydrological consequences.

7. International Cooperation & Water Resource Management:

- Transboundary Impacts: The Yarlung Tsangpo is a major international river, making its development highly politically sensitive. Large-scale hydropower projects raise legitimate concerns among downstream nations (primarily India, Bangladesh) regarding water utilization (volume, timing), sediment flow, ecological effects, and potential flood risks.

- Data Sharing & Coordination: Rigorous environmental monitoring and assessment, sharing hydrological data (especially flood data), and establishing effective water resource coordination mechanisms, adhering to principles of international water law (e.g., equitable and reasonable utilization, prevention of significant harm), are crucial to mitigating potential disputes. Transparency and communication are paramount.

8. Integrated Monitoring & Smart Operation:

- Lifecycle Health Monitoring: After completion, a comprehensive, real-time, intelligent monitoring network (using sensors, IoT, satellite remote sensing) covering dams, powerhouses, tunnels, slopes, foundations, electromechanical equipment, and transmission systems must be established. Integrating this with BIM/GIS and big data analytics enables precise structural safety and operational status awareness and early warning.

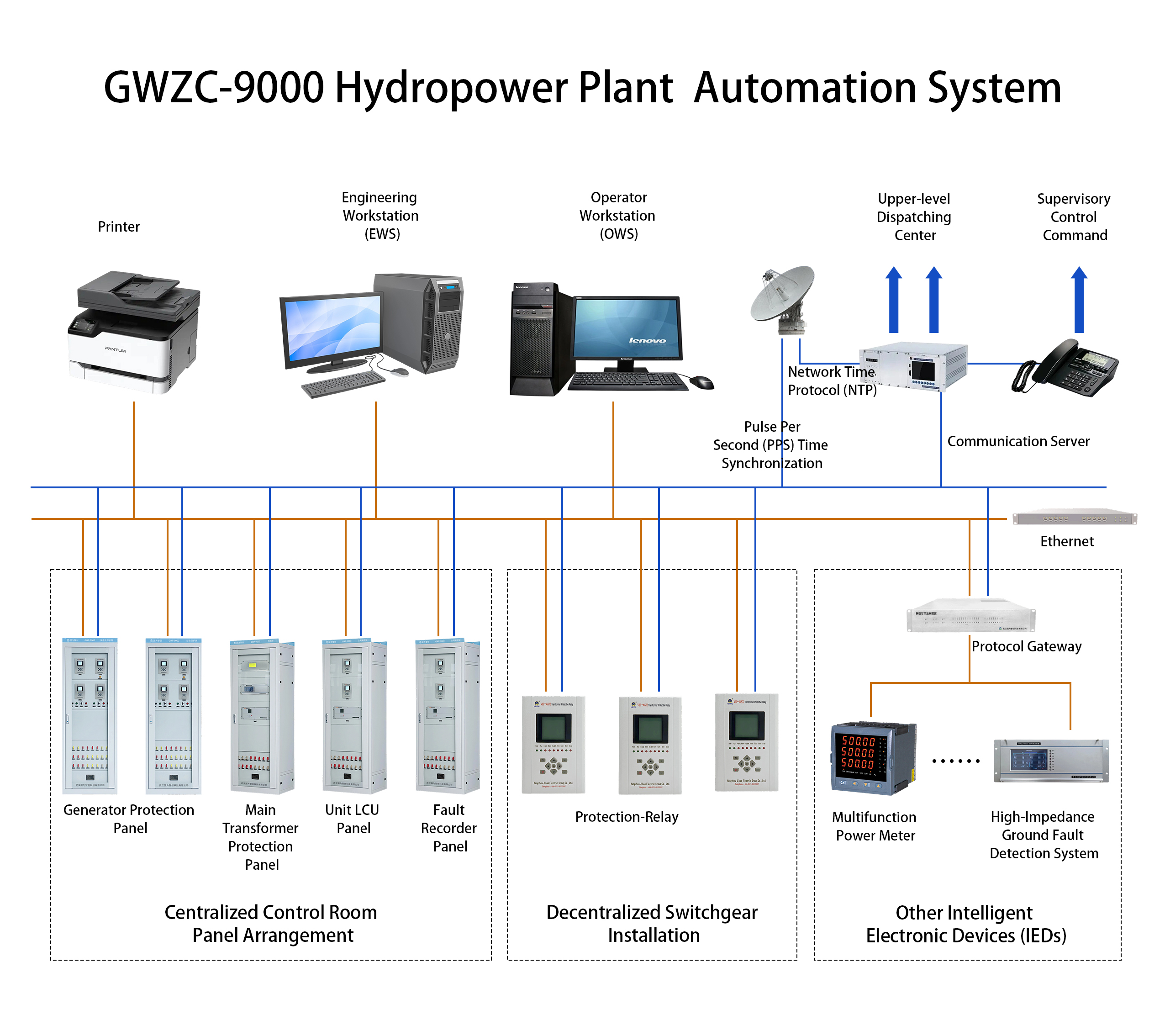

- Smart O&M Decision Support: Utilizing AI, digital twin technology, etc., SCADA system,for equipment condition assessment, fault diagnosis, risk prediction, and optimized scheduling is essential for achieving intelligent, potentially partly remote and automated operation and maintenance (O&M) of such ultra-large, ultra-complex hydropower projects.

Summary:

The technical challenges of Yarlung Tsangpo hydropower, particularly the Motuo station, encompass virtually all the extreme domains of hydro engineering: Immense hydraulic head, intense seismicity, extreme geology, gigantic capacity, super-long tunnels, ultra-deep burial, ultra-high head, UHVDC transmission, construction in an extreme environment, ecological fragility, and international complexity. This is a “megaproject” requiring the integration of cutting-edge advancements across numerous disciplines: geological survey, geotechnics, structural mechanics, hydraulics, turbine manufacturing, power systems, materials science, construction technology, smart monitoring, environmental protection, and international relations. Its technical difficulty and risk far exceed those of the Three Gorges project, representing humanity’s apex effort to build large energy infrastructure under nature’s most extreme conditions. Every step forward demands rigorous scientific validation, extensive technological breakthroughs, and international cooperation and coordination. In essence, it aims to harness the world’s mightiest river resources in its most complex geological region to construct one of the planet’s largest hydroelectric power plants – arguably the peak challenge in global hydropower engineering.