I. Basic Information on Standard Publication

1.Standard Names & Numbers:

IEC 63522-6:2025 Electrical Relays – Tests and Measurements – Part 6: Contact Circuit Resistance (or Voltage Drop)

IEC 63522-35:2025 Electrical Relays – Tests and Measurements – Part 35: Resistance to Cleaning Agents

IEC 63522-36:2025 Electrical Relays – Tests and Measurements – Part 36: Fire Hazard

2.Issuing Body: International Electrotechnical Commission (IEC)

3.Leading Organization: Xiamen Hongfa Electroacoustic Co., Ltd. (China) (World’s largest relay manufacturer, ranked first globally in market share for consecutive years)

4.Release Date: February 2025 (Parts -6 and -36) / May 2025 (Part -35)

II. Technical Specifications of the Three Core Standards

1. IEC 63522-6:2025: Contact Circuit Resistance (or Voltage Drop)

Scope: Standardizes test methods for circuit resistance or voltage drop of relay contacts in the closed state.

Key Requirements:

Verify that contact resistance remains within specified limits to ensure long-term conductive stability;

Quantify resistance changes caused by contact oxidation/wear to prevent circuit failure.

Test Method: Apply rated current via a constant current source; measure voltage drop across contacts and calculate resistance.

2. IEC 63522-35:2025: Resistance to Cleaning Agents

Scope: Tests corrosion resistance of relays exposed to industrial chemical cleaning agents.

Key Requirements:

Simulate material tolerance after exposure to cleaning agents (e.g., solvents, acids/alkalis) during manufacturing or maintenance;

Evaluate impacts of seal aging and metal contact corrosion on product lifespan.

Test Method: Accelerated aging tests; record material deformation and electrical performance degradation.

3. IEC 63522-36:2025: Fire Hazard Assessment

Scope: Fire safety performance of relays under abnormal operating conditions.

Key Requirements:

Ensure relays do not ignite during overload/short-circuit, or that flames self-extinguish within defined time/range;

Restrict use of flammable materials to mitigate fire risks.

Test Method: Apply fault current; monitor temperature rise, smoke emission, and ignition; record flame duration.

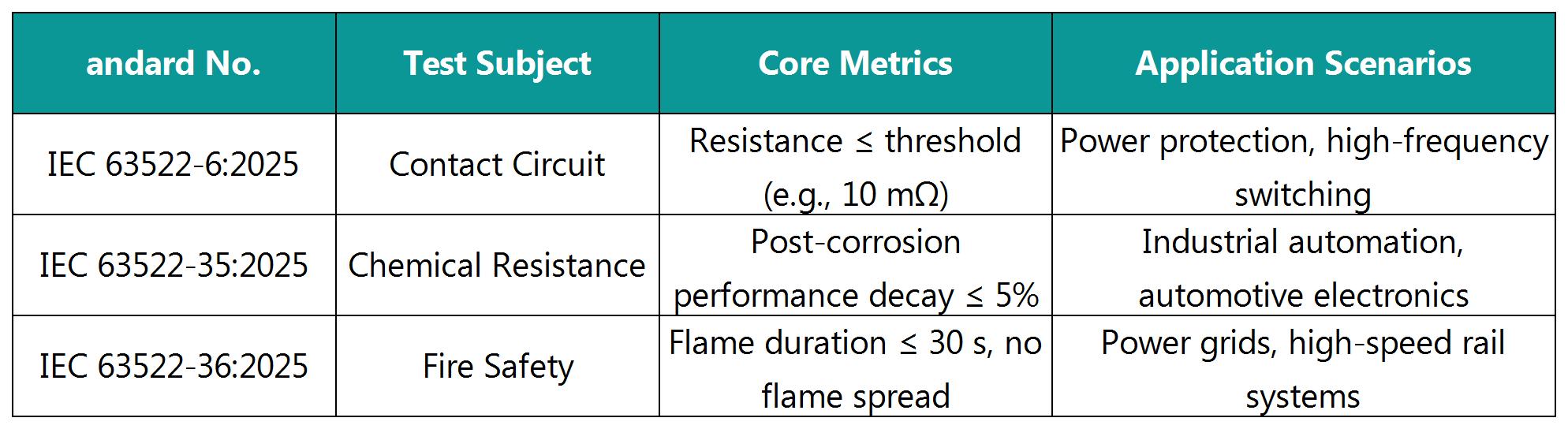

Table: Key Technical Parameters and Test Objectives

III. Standard Development Background & Process

1.Technical Drivers:

Previous IEC standards (2006) lagged behind reliability/safety requirements for relays in emerging fields (e.g., renewable energy, smart grids);

Global absence of unified corrosion/fire safety test protocols caused product quality inconsistencies.

2.China’s Leading Role:

Xiamen Hongfa convened multinational experts, proposing test protocols based on its global engineering expertise (>50% market share);

Validated methodology via experimental data (e.g., accelerated aging datasets) after >20 technical debates.

3.Timeline & Challenges: Finalized after 3 years; key disputes (e.g., fire-test current thresholds, cleaning agent concentration) resolved with Chinese proposals as baseline.

IV. Significance of Standard Publication

1.Technical Advancement:

Establishes unified global test benchmarks, reducing trade barriers from standard disparities;

Drives relays toward higher reliability/longevity (e.g., 100,000-operation lifespan for EV relays).

2.Industrial Competitiveness:

Elevates China from “manufacturing hub” to “standard-setting leader”, enhancing global pricing power;

Benefits Xiamen relay industrial cluster (5 manufacturers + 21 upstream/downstream firms) via technical spillover.

3.Safety & Sustainability:

Reduces fire risks in critical infrastructure (e.g., high-speed rail power networks);

Minimizes industrial e-waste through corrosion-resistance standards.

V. Industry Impact & Future Outlook

Short Term: Mandatory compliance in regions (e.g., EU); Chinese testing bodies gain first-mover advantage.

Long Term: China plans standards for intelligent, low-power relays, synchronizing domestic/international development.

Challenge: SMEs face cost pressures from production-line upgrades (e.g., fire-resistant materials).

Note: Terminology strictly adheres to IEC norms, e.g., “Contact Circuit Resistance,” “Fire Hazard.” Refer to IEC 63522 series for original text.