In regions with high humidity, condensation frequently occurs. While the primary circuit is sealed within the gas compartment and remains unaffected, protective measures must be implemented for the operating mechanism, secondary circuits, and special attention should be paid to condensation in the fuse compartment. For instance, an industrial user in Australia installed a ring main unit (RMU) inside an outdoor enclosure. The unit was powered on in the morning and switched off at night, resulting in no load during non-operational hours. One day, during a fuse replacement, severe corrosion was found on the fuse holder. Although the fuse compartment cover and the compartment itself were fully sealed, meeting IP67 requirements, and the compression of the silicone rubber ensured the power-frequency withstand voltage between the high-voltage fuse and the cabinet, it was initially perplexing how moisture could have entered the fuse compartment.

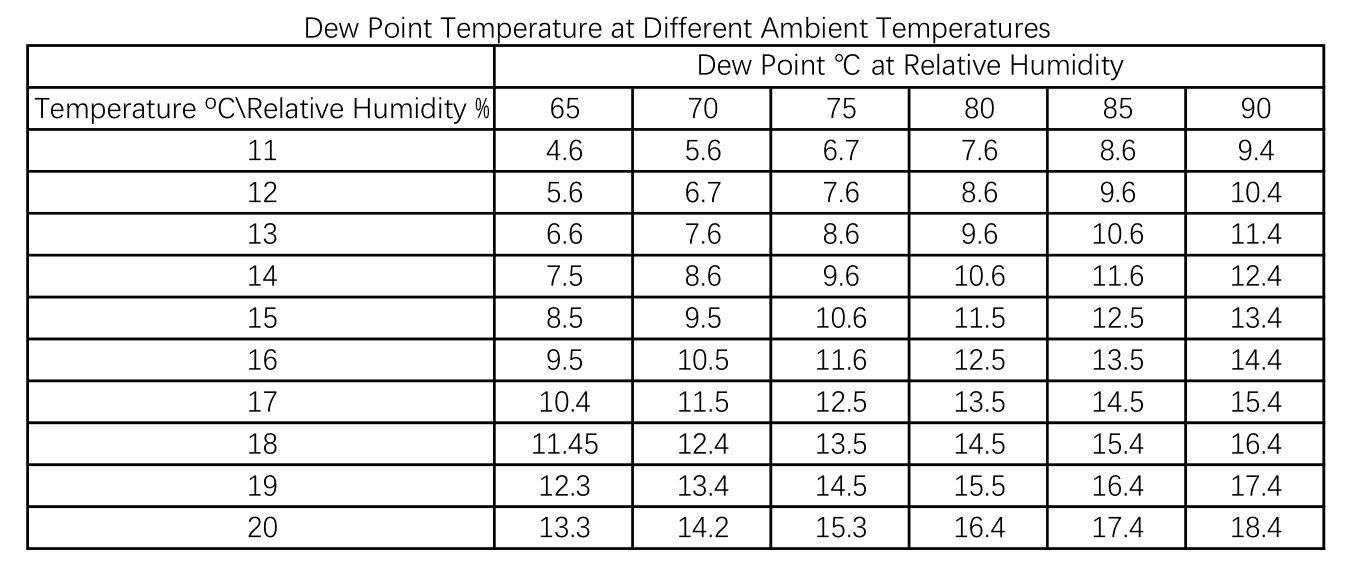

Considering that the equipment was installed in a coastal area of Australia, and the fuse was configured and installed on-site by the customer during the summer season when humidity is high, the dew point under relative humidity conditions is shown in the figure below.

Assuming the temperature during fuse installation was 20°C with 80% relative humidity, according to Table 2, the dew point is 16.4°C. The installation process took a prolonged period, and after completion, the fuse compartment was sealed. Under ideal conditions where the interior of the compartment is completely isolated from the external environment, condensation occurs inside the enclosure when the internal temperature drops to the dew point. Suppose the ambient temperature during fuse installation was 25°C with 60% relative humidity. Since the interior of the insulation cylinder is isolated from the outside, the initial temperature and humidity of the air inside the compartment correspond to those during the fuse installation. According to the table below, the dew point temperature is 16.7°C. As the equipment was shut down at night, the external ambient temperature dropped to only 5–10°C. The dew point temperature for condensation formation remained lower than the ambient temperature. Inside the fuse cylinder, condensation inevitably occurred where the air temperature was lowest. The coolest part of the fuse cylinder is the fuse compartment cover. Consequently, the fuse clips on the fuse cylinder cover reached the dew point temperature, leading to condensation. This process repeated cyclically, resulting in silver plating oxidation and severe corrosion of the fuse holder.

Therefore, for ring main units used in such applications, it is essential to keep the high-voltage fuse compartment dry. During fuse replacement, humidity conditions must be met, and exposure time should be minimized. If necessary, switchgear cabinets should be used instead of combination apparatus cabinets.