The typical service life of medium-voltage switchgear is approximately 20 years. After prolonged operation, various issues may arise, such as insulation aging, increased temperature rise, circuit breaker mechanism jamming, and loss of vacuum, all of which pose significant risks to continued operation. Replacing entire units requires substantial financial investment and time, whereas retrofitting offers a rapid solution to address safety hazards, revitalize the equipment, and ensure continued safe operation.

Challenges in Retrofitting

Although switchgear does not undergo rapid product updates like consumer electronics, advancements have been made, including reduced dimensions and optimized insulation components. Original equipment may no longer be in production due to manufacturer mergers, acquisitions, or restructuring, making it difficult to source compatible parts. For imported equipment, changes in companies may lead to the closure of import channels for components. However, some original equipment remains in excellent condition even after 20 years of service and requires retrofitting or capacity expansion.

Primary Retrofit Solutions Include:

Insulation component upgrades

Circuit breaker replacement

Control system modernization

Circuit Breaker Retrofitting

Prefabricated interfaces compatible with existing equipment enable rapid replacement.

1.Replacement of the circuit breaker only: A new draw-out unit identical to the original breaker is manufactured for quick replacement. For example, GE’s VB1 circuit breakers, widely used in power plants and American-invested enterprises in China two decades ago, offer excellent performance. Modern solid-insulated breakers can be installed on draw-out units identical to the original, ensuring seamless integration into the existing switchgear. The primary contact system and secondary control system must match the original breaker for uninterrupted operation.

In principle, the new circuit breaker assembly, including the base and contact arm system, must undergo dynamic and thermal stability tests, T100 breaking tests, and temperature rise tests to verify overall performance meets system requirements.

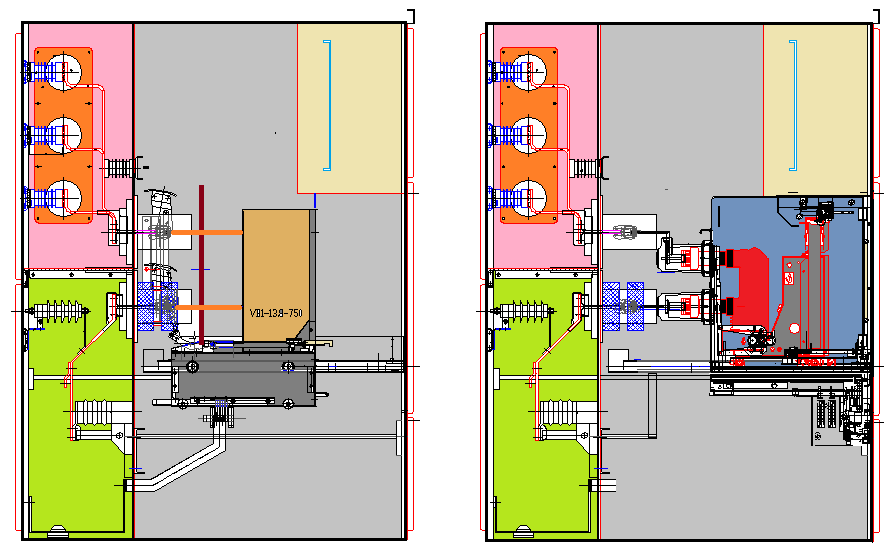

Retaining the original circuit breaker compartment interface: Instead of modifying modern circuit breakers, a new compartment or frame equipped with rails, contact housings, etc., can be designed. This assembly connects to the existing switchgear circuit via rear contacts and busbars, facilitating replacement. New-generation solid-insulated breakers are generally more compact than older models, making replacement easier and enabling intelligent upgrades.

a. L-Frame Solution: An L-shaped frame equipped with rails, shutter drive mechanism, shutter plates, primary contacts, and insulated contact housings is precision-assembled in the factory to ensure exact alignment with the circuit breaker. The entire assembly is installed in the existing switchgear compartment, restoring breaker functionality.

-1.png)

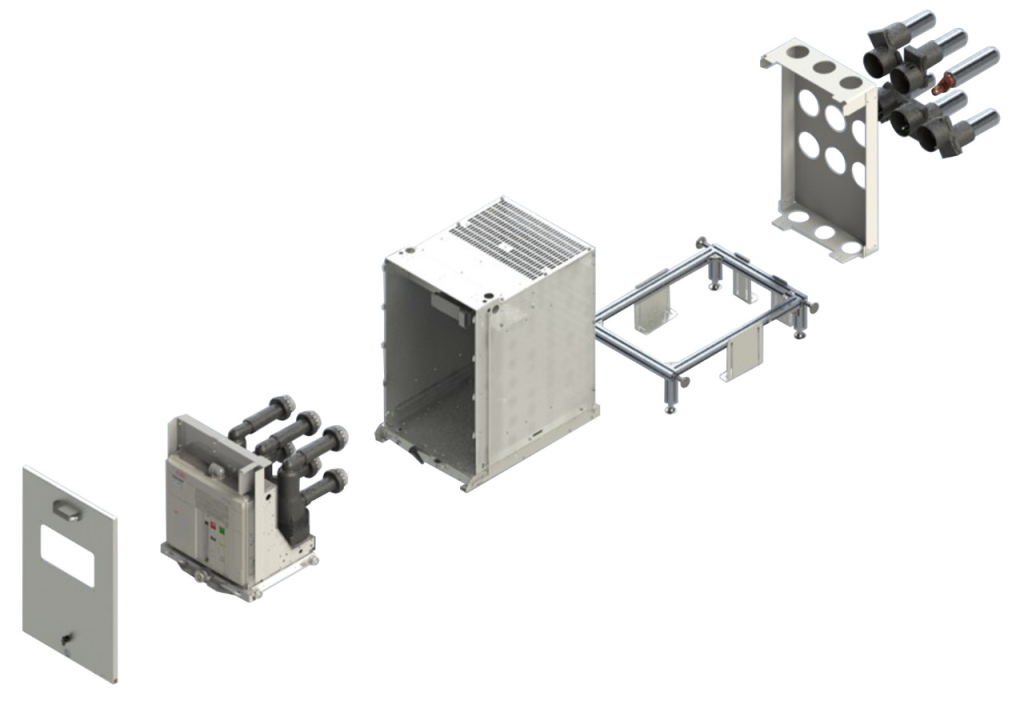

b. BOX Frame Solution: Utilizing the original contact housing system, a compact circuit breaker and its compartment are equipped with a contact adaptation system that directly connects to the stationary contacts of the existing switchgear. This eliminates the need for on-site busbar connections and enables rapid replacement.

This approach requires no modifications to the circuit breaker, as standard products are used. The base frame must meet dynamic and thermal stability requirements.

2.Replacing the circuit breaker compartment also enables integration of intelligent features, such as current sensors embedded in the contact housings for current monitoring and protection functions.

Busbar Insulation System Retrofit

Replacing contact housings, insulators, wall bushings, and the entire busbar system with new components is challenging when original insulation parts are unavailable. For some switchgear, such as older 40.5 kV Air-Insulated Switchgear a width of 1,818 mm and a depth of 3.2 meters, retrofitting is relatively straightforward due to ample space. For example, upgrading to KYN61-style contact housings and busbar arrangements is feasible, and busbar connections can be easily adapted. However, for switchgear with compact busbar compartments, solid insulation, or unique connection designs, retrofitting is more complex. If the customer agrees, raising the height of the compartment can create additional space for busbar reconfiguration. Otherwise, sourcing parts from original suppliers or replicating the insulation process may be necessary to achieve equivalent insulation performance.

Secondary System upgrades

The secondary system can be enhanced by installing state-of-the-art multifunctional protection relays and replacing secondary wiring and terminals.