For Gas-Insulated Switchgear (GIS), since the main live circuits are enclosed within sealed, gas-filled compartments and external connections utilize solid insulation, the insulation performance is unaffected by atmospheric pressure. The primary consideration for GIS at high altitudes is the mechanical strength of the gas enclosure (gas compartment).

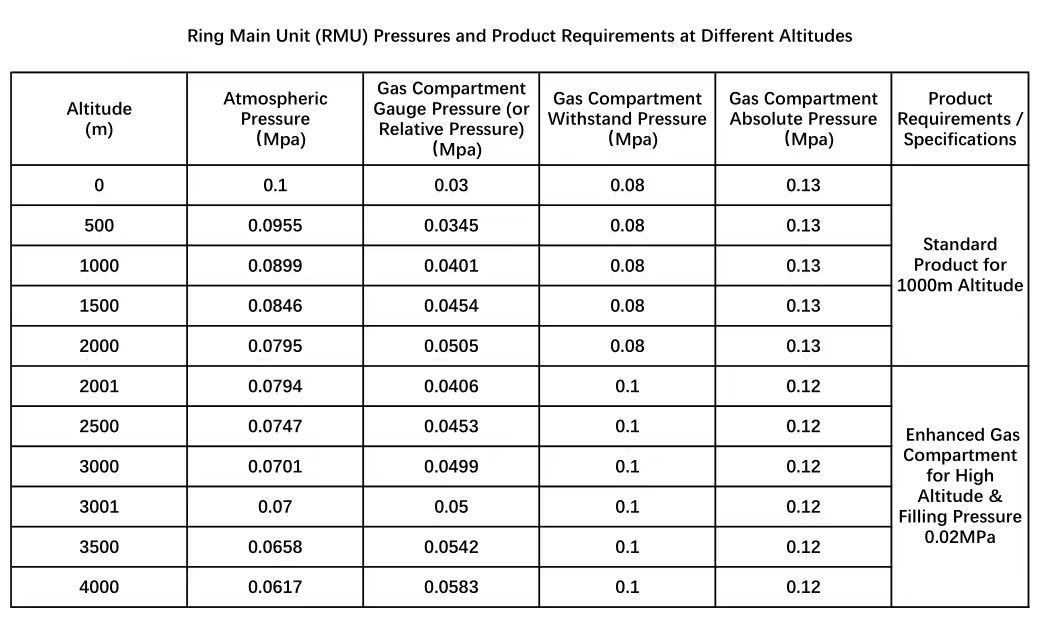

In countries like Chile in South America and the southwestern regions of China, altitudes often exceed 2000 meters. For GIS such as SF6-insulated Ring Main Units (RMUs) or compact switchgear, the main impact of altitude relates to the effect of atmospheric pressure variation on the enclosure’s strength. Because the primary live circuit is completely sealed within the gas compartment, its insulation performance is determined by the absolute pressure of the insulating gas inside. For example, if the filling pressure is 0.13 MPa absolute pressure, at low altitude (standard atmospheric pressure ≈ 0.101 MPa), the relative pressure (gauge pressure) is 0.03 MPa. Crucially, the enclosure’s structural strength is determined by the relative pressure (pressure difference), not the absolute pressure. According to the GB/T 3906 standard (equivalent to IEC 62271-200), the design pressure for pressurized compartments is specified as relative pressure. Consequently, pressure testing is based on this design relative pressure.

At an altitude of 3500 meters, atmospheric pressure is approximately 0.065 MPa. Assuming a filling absolute pressure of 0.14 MPa, the pressure difference across the enclosure wall at 1000 meters altitude would be 0.04 MPa. However, at 3000 meters altitude, this pressure difference increases to 0.075 MPa (0.14 MPa abs – 0.065 MPa abs). While this might be below the 3x design pressure test threshold, it could exceed 1.3 times the design pressure. This means that, according to standards, the pressure relief device could potentially activate. Even if some designs have a maximum withstand pressure of 0.07 MPa (relative) where the relief device wouldn’t operate, the enclosure could bulge. In severe cases, this could lead to rupture of the enclosure, causing gas leakage and accidents.

Common mitigation strategies include:

Using reinforced enclosures with strengthened pressure relief devices and sealing systems.

Adding reinforcing ribs to the enclosure via welding to enhance its pressure resistance capability.

Minimizing the filling pressure to the lowest level sufficient to meet insulation requirements.

It is essential to consider not only operational conditions but also transportation routes, especially if they pass through high-altitude areas. Transporting at reduced pressure or atmospheric pressure helps maintain the product’s gas tightness and prevents damage to the enclosure’s structural integrity. Air transport requires particular attention to pressure variations to avoid damage to the enclosure and sealing system from excessive pressure differentials.

Cable connection bushings and cable terminations for GIS must also be considered for high-altitude applications. Theoretically, since they are not air-insulated external insulation, altitude might seem irrelevant. However, failures can occur during practical use or testing. Therefore, using bushings rated for a higher voltage class is advisable to avoid insulation failures potentially caused by imperfect installation or incomplete sealing.

Secondary systems, particularly components like contactors, are fully exposed to the low-pressure ambient air. At higher altitudes, temperatures are generally lower. This temperature reduction can affect the electrical conductivity, mechanical strength, and service life of electronic components.

As altitude increases, air density decreases. Switching components and arc quenching systems often rely on air for arc extinction. Air density is a critical factor for arc quenching effectiveness. Relevant standards include:

GB/T 14048.1-2012 (equivalent to IEC 60947-1: Low-voltage switchgear and controlgear – Part 1: General rules)

GB/T 20626.1-2006 (equivalent to IEC 60721-3-3: Classification of environmental conditions – Part 3-3: Classification of groups of environmental parameters and their severities – Stationary use at weatherprotected locations – *Note: Specific high-altitude requirements for electronics are often covered under product family standards or IEC 60721 series for environmental conditions*).

Low-voltage control components for secondary systems in high-altitude applications must comply with the above standards. Testing and verification are recommended when necessary.