Underground mining switchgears and ordinary surface switchgears differ significantly in application environment, technical requirements, safety standards, and other aspects. The following is a comparative explanation from multiple key dimensions:

1. Differences in Environmental Adaptability

Underground mining switchgears: They must adapt to hazardous environments with high humidity (usually humidity > 95%), high dust levels (including coal dust, rock dust, etc.), risks of gas/coal dust explosions, and potential impacts from vibration, shock, and corrosive gases (e.g., hydrogen sulfide). Their enclosure protection rating must reach IP65 or higher, and some special scenarios require compliance with explosion-proof ratings (such as Ex d I) to prevent electric sparks from triggering explosions.

Ordinary surface switchgears: They are mainly used in dry, clean indoor environments (e.g., substations, distribution rooms) with ambient humidity generally < 85% and no explosion risks. The enclosure protection rating is usually IP3X – IP54, and no explosion-proof design is required.

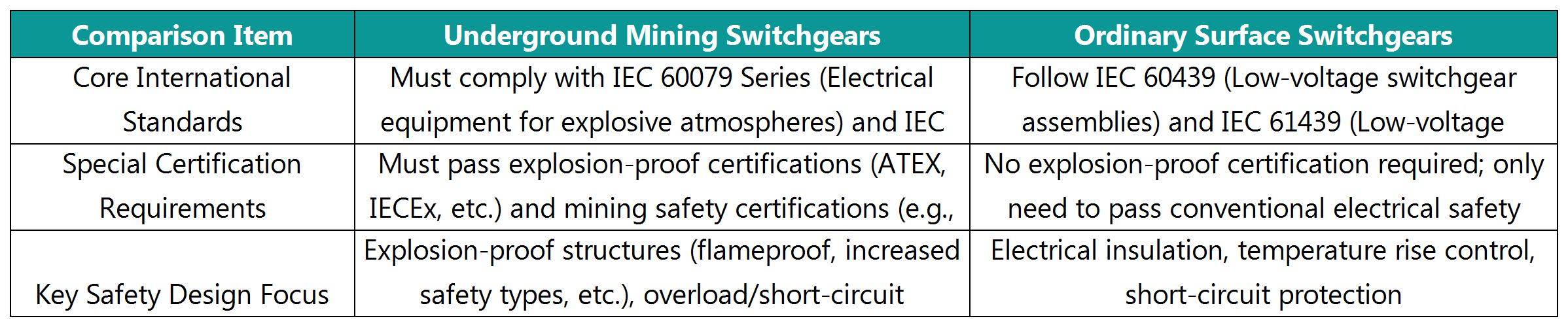

2. Differences in Safety Standards and Certifications

3. Differences in Structure and Materials

Enclosure materials: Underground mining switchgears mostly use high-strength cast steel or stainless steel with greater thickness (usually ≥ 6mm) to withstand explosion impacts; ordinary surface switchgears commonly use cold-rolled steel sheets with thinner thickness (2 – 4mm), and their surfaces only undergo anti-corrosion painting.

Internal structure: Components inside underground switchgears must be firmly fixed, adopting flameproof chamber designs, and cable entries use explosion-proof sealed joints; surface switchgears have a lighter structure, flexible layout, and no mandatory flameproof requirements.

4. Differences in Functions and Performance

Protection performance: Underground switchgears have waterproof, dustproof, and corrosion-resistant capabilities, and some models integrate online temperature/humidity monitoring and automatic dehumidification functions; surface switchgears focus on ventilation and heat dissipation, with some equipped with fans or heat sinks, and no special dehumidification needs.

Operational stability: Underground switchgears must operate stably in a wide temperature range of -20℃ – +40℃, with a vibration resistance rating ≥ IEC 60068-2-6 (vibration testing); surface switchgears have a narrower operating temperature range (-5℃ – +40℃) and lower vibration resistance requirements.

5. Differences in Application Scenarios and Maintenance

Application scenarios: Underground mining switchgears are used for power distribution control in underground mining faces and roadways of coal mines, metal mines, etc., directly serving equipment such as roadheaders and conveyors; surface switchgears are used for power distribution and control in ground facilities such as factories, substations, and buildings.

Maintenance requirements: Maintenance of underground switchgears must strictly follow explosion-proof regulations. Before opening the cover for maintenance, power must be cut off and environmental gas concentration must be detected; maintenance of surface switchgears is simpler, requiring only regular inspections without special gas detection procedures.

Summary

The core design of underground mining switchgears is “explosion-proof and resistant to harsh environments”, requiring safety and reliability under extreme conditions; while ordinary surface switchgears focus more on “efficient power distribution and cost optimization”, adapting to electrical control needs in conventional environments. The differences between them in standard systems, material selection, and structural design all stem from the essential differences in application scenarios.