The miniaturization of switchgear is a common demand in the IEC market. For instance, the standard dimensions for 13.8kV (17.5kV), 1250A switchgear are typically 600mm in width and 2100mm in height, while 3150A versions are generally only 900mm wide.

However, 36kV air-insulated switchgear typically has a width of 1000mm, with a maximum current rating of 3150A. Some domestic manufacturers use 40.5kV switchgear as a substitute, but these generally have a width of 1400mm, which is often difficult for high-end clients to accept.

So, how can we design miniaturized 36kV switchgear? Firstly, it’s essential to clarify the insulation requirements. The rated voltage of 36kV corresponds to a power-frequency withstand voltage of 70kV, which is 74% of the 95kV required for GB 40.5kV switchgear. Its lightning impulse withstand voltage is 170kV, which is 92% of the 185kV required for GB 40.5kV switchgear. This understanding allows for targeted design of the switchgear.

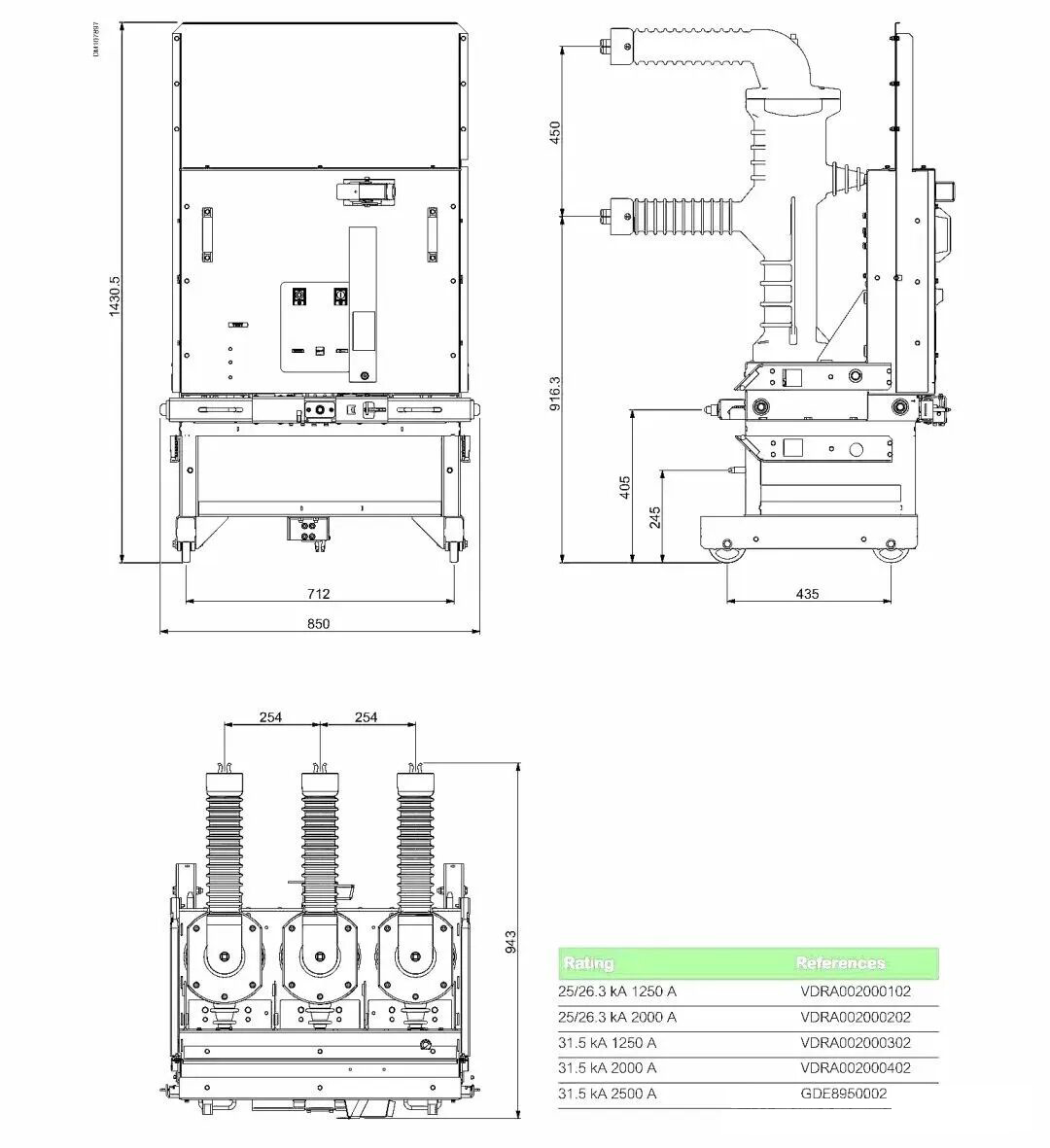

Regarding the circuit breaker itself, the typical phase-to-phase distance is 275/300mm, with a pole unit diameter of 200mm. Typically, the circuit breaker chassis width is only 2×300 + 200 = 800mm. For 36kV circuit breakers with smaller phase-to-phase distances, the chassis width can be further reduced.

For example, with a phase spacing of 10 inches (254mm) and a wheelbase of 712mm, the switchgear width could be designed as 1000mm, or even smaller.

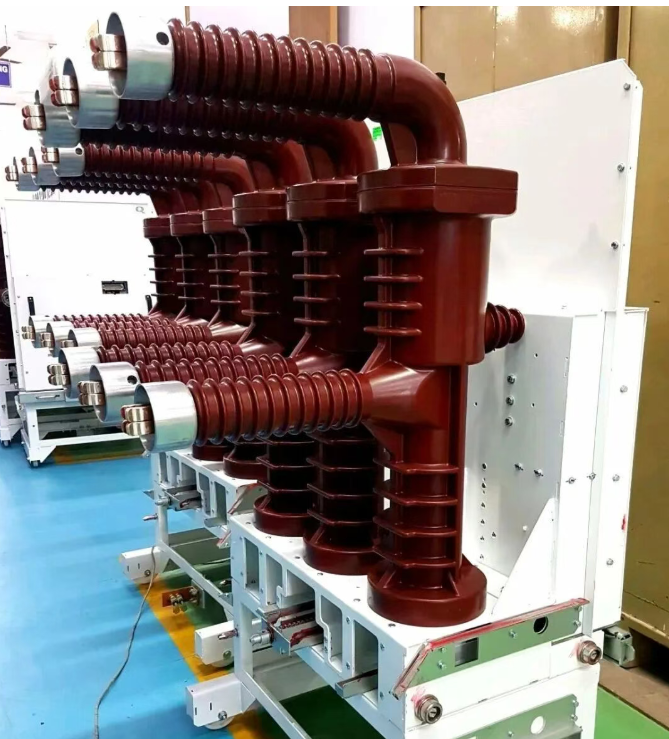

Conventional 36kV circuit breakers feature a phase spacing of 275mm. The breaker poles are fully insulated, and the moving contacts (arms) are solid-insulated all the way to the contact tips, with only the very tips remaining uninsulated.

Conventional 36kV circuit breakers have a phase spacing of 275mm. The breaker pole units are fully insulated, and the moving contacts (arms) are solid-insulated up to the contact tips, with only the very tip being uninsulated.

The front compartment depth is 1000mm. The breaker rack-in depth is 360mm, which implies a distance of 300mm from the stationary contacts to the shutters. The folding shutter mechanism requires a 30mm travel to open fully. The tulip contacts and stationary contacts have an engagement depth of 30mm.

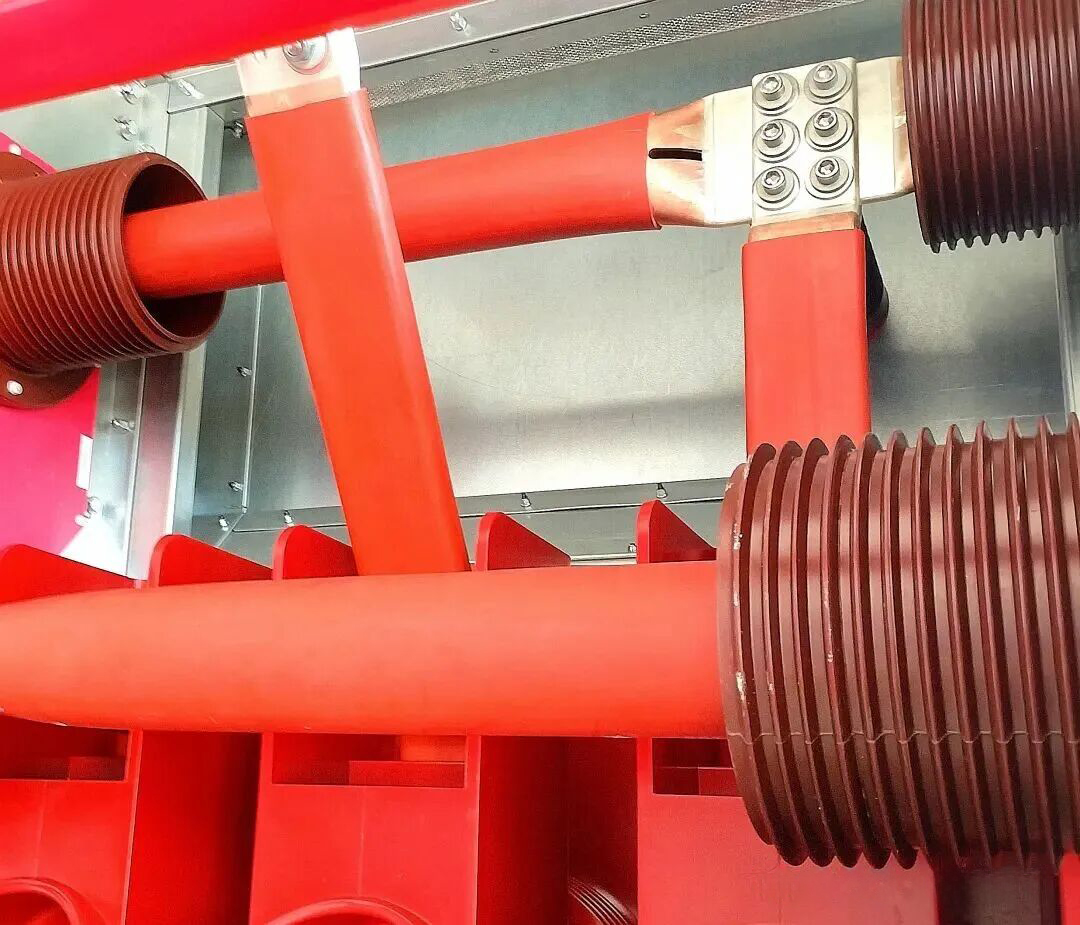

To ensure electrical insulation between the shutters and the stationary contacts, GPO-3 laminated plates are used. These plates have a thin metal sheet pressed in the center, which provides insulation while also meeting the requirements for the PM (Partition Metal-clad) separation type in switchgear.

The use of tubular busbars significantly reduces the required clearances in air. Particularly with large-diameter tubular busbars, a tube with an outer diameter of 100mm and a wall thickness of 10mm can carry a current of 3150A.

For the RAYCHEM Type BBIT bushing, the phase-to-phase clearance for rectangular copper bars is 140mm, and the phase-to-earth clearance is 190mm. It also very reasonably indicates that the required spacing for round busbars is less than for rectangular bars. When using circular tubular busbars, a phase-to-phase clearance greater than 100mm and a phase-to-earth clearance greater than 160mm are sufficient, provided the air clearance is greater than 320mm.

The clearances for tubular busbars can all meet the requirements mentioned above. A larger diameter leads to a more uniform electric field. For instance, with a 3150A, 100mm diameter busbar, the phase-to-phase air clearance is 275 – 100 = 175mm, which is greater than the minimum distance required for heat-shrink tubing. In a 1000mm wide switchgear panel, the phase-to-earth distance is (1000 / 2) – 275 – 50 – 4 = 171mm, exceeding the required 160mm.

Regarding temperature rise under high current conditions, the compact switchgear design first leads to shorter copper busbar lengths, resulting in lower heat generation. Secondly, the compact wind channel design facilitates better heat dissipation.

Additionally, GPO-3 insulation plates are used on both sides of the cable compartment and between phases within the switchgear, providing dual protection. In the event of an internal arc fault, these GPO-3 plates can also help prevent the arc from expanding and reduce arc exposure to earth.

The current transformers used are IEC 36kV type transformers, which have a compact size and their functionality meets the requirements of IEC customers