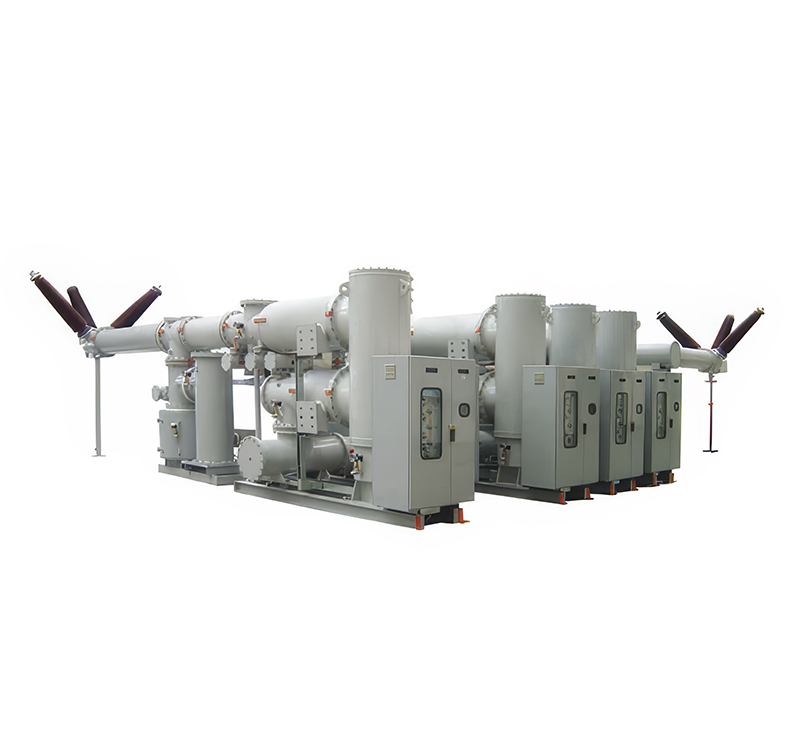

Scope of Application:SF₆ gas-insulated switchgear (GIS) is designed for 3.6kV to 800kV AC power systems, covering medium voltage (MV), high voltage (HV), and extra-high voltage (EHV) applications. It is particularly suited for space-constrained installations and mission-critical environments (e.g., urban grids, rail transit, offshore wind farms, industrial plants, and extreme climates), complying with IEC 62271-200/203.

Voltage Levels (per IEC 60038):

Medium Voltage (MV): 3.6kV, 7.2kV,11KV, 12kV, 24kV, 36kV

High Voltage (HV): 72.5kV, 145kV, 245kV

Extra-High Voltage (EHV): 362kV, 420kV, 550kV, 800kV

Rated Current: 400A–6,300A (up to 8,000A for HV/EHV)

Short-Circuit Breaking Capacity: 16kA–80kA (1s thermal withstand)

Insulation Medium: SF₆ gas (rated filling pressure: 0.4–0.7MPa at 20°C)

1.Product Overview

SF₆ gas-insulated switchgear (GIS) integrates circuit breakers (CB), disconnectors (DS), earthing switches (ES), current/voltage transformers (CT/VT), and busbars within SF₆-filled metal enclosures. Compliant with IEC 62271 series, its compact design leverages SF₆’s high dielectric strength (≈3× air) and superior arc-quenching capability (arcing time <15ms).

Key advantages:

Environmental Resilience: IP67-rated for operation at -30°C to +40°C, ≤95% humidity, or altitudes up to 4,000m.

Safety: Segregated gas compartments (individual gas zones per bay), leakage rate <0.5%/year (IEC 62271-303).

Smart Grid Integration: Supports IEC 61850-9-2LE for digital substation interoperability.

Eco-Friendly Options: SF₆/N₂ mixtures or alternative gases (e.g., C₅-PFK) to reduce GWP.

2.Primary Functions

Circuit breaking/closing operations (per IEC 62271-100)

Short-circuit current interruption & load switching

Isolation and earthing (per IEC 62271-102/103)

Condition monitoring (partial discharge, gas density, mechanical characteristics)

3.Product Functions

Electrical Performance

Circuit Breaker: Puffer-type or self-blast interrupter, breaking time ≤3 cycles (60ms).

Isolation/Earthing: Three-position switch (DS+ES) with mechanical interlocks (IEC 62271-102).

Measurement/Protection: Rogowski coils (CT) or capacitive dividers (VT), accuracy class 0.2 (IEC 60044).

Smart Monitoring

Gas Management: Density relays (alarm: 0.45MPa, lockout: 0.4MPa) + moisture monitoring (≤200ppm).

Mechanical Diagnostics: Travel sensors for contact speed (±10% tolerance) and wear prediction.

Partial Discharge Detection: UHF sensors (300MHz–1.5GHz) or TEV sensors (3MHz–100MHz).

4. Technical Parameters

5.Key Features

Technical Superiority

Compact Footprint: Occupies 10%–30% space of AIS (e.g., 25㎡ vs. 100㎡ for 145kV).

Maintenance-Free: Sealed design, maintenance interval ≥15 years (IEC 62271-301).

Rapid Deployment: Modular pre-assembly reduces on-site installation time by 60%.

Safety & Sustainability

Non-Flammable: Eliminates fire hazards (vs. oil-filled equipment).

Low Noise: Operation noise <75dB (AIS typically >90dB).

Eco-Compliance: Integrated SF₆ recovery unit (per IEC 60480).