Scope of Application:11kV switchgear serves as the core equipment for power distribution, circuit protection, and system control in industrial plants, commercial buildings, and renewable energy power stations. Compliant with IEC 62271-200 standards for metal-enclosed switchgear, it is designed for indoor installation. Typical applications include factory distribution rooms, commercial complex substations, hospital backup power systems, and photovoltaic plant grid connections. The design supports various configurations, including radial, ring-main, and double-busbar systems.

Rated Voltage: suitable for 15KV/12KV/11kV/10KV distribution systems

Rated Current: Standard ratings of 630A, 1250A, 1600A, 2000A, 2500A, and 3150A

Short-Circuit Withstand Current: 20kA/1s, 25kA/1s, 31.5kA/1s, and 40kA/1s

Insulation Medium: Air-insulated (AIS) or SF₆ gas-insulated (GIS)

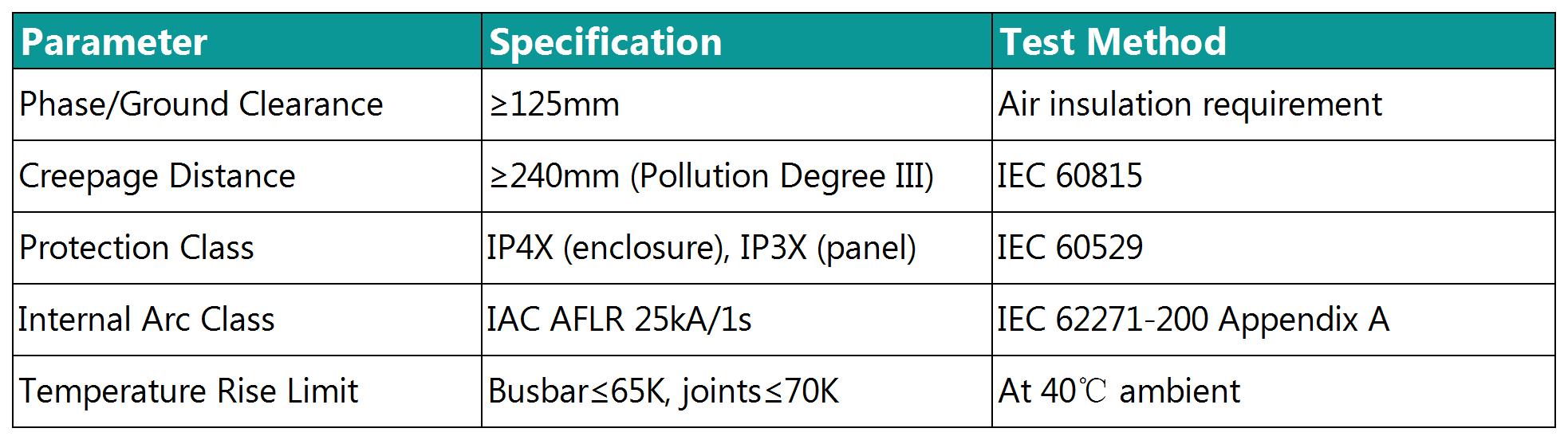

Protection Class: IP4X (internal enclosure), IP3X (control panel)

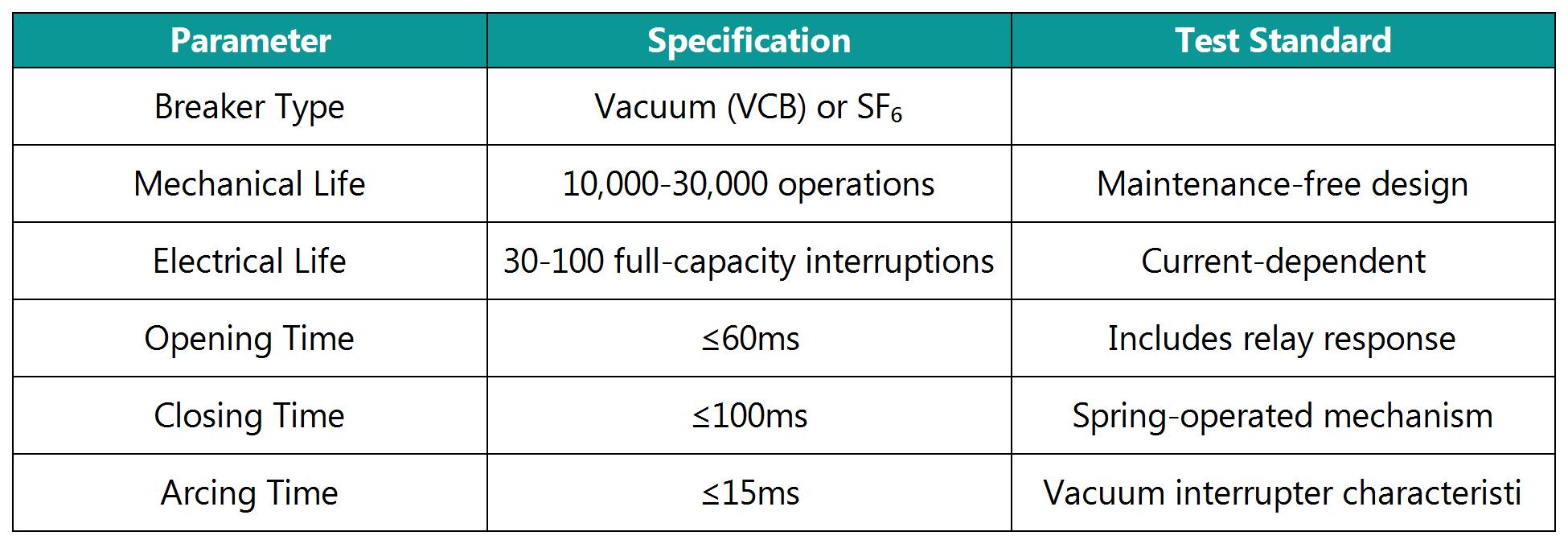

Circuit Breaker Type: Vacuum circuit breaker (VCB) or SF₆ circuit breaker

Operating Mechanism: Spring-operated or motor-driven spring-operated

1.Product Overview

11kV metal-enclosed switchgear is a critical component of medium-voltage distribution systems. It adopts a modular design philosophy, integrating vacuum circuit breakers, disconnectors, current/voltage transformers, protective relays, and control units within metal-enclosed compartments to form a complete power distribution solution.

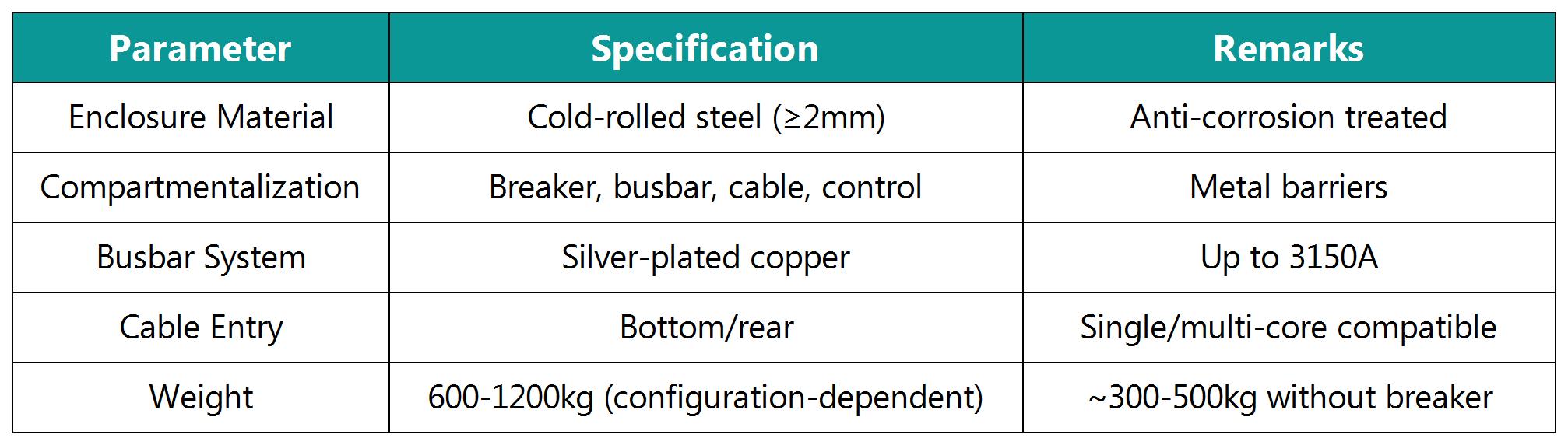

In accordance with IEC 62271-200, the equipment is divided into multiple functional compartments, including the circuit breaker compartment, busbar compartment, cable compartment, and low-voltage control compartment. These compartments are effectively segregated by metal partitions or insulating barriers to ensure operational safety and maintenance convenience.

Modern 11kV switchgear typically employs vacuum circuit breakers as the interrupting medium, offering environmental advantages and maintenance-free operation compared to traditional SF₆ circuit breakers. Vacuum interrupters can clear short-circuit currents of up to 40kA within 10-15ms, working in conjunction with spring-operated mechanisms to ensure fast and reliable switching operations.

The busbar system is usually constructed with silver-plated copper bars to minimize contact resistance, supporting rated currents of up to 3150A for high-capacity distribution requirements. The enclosure is made of high-quality cold-rolled steel (≥2mm thick) with anti-corrosion treatment and is tested for internal arc fault resistance (IAC AFLR) to ensure personnel safety in case of internal faults.

For protection and control, 11kV switchgear can be equipped with multifunctional digital relays to provide comprehensive protection functions, including overcurrent, earth fault, and arc-flash protection. Communication interfaces (IEC 61850, Modbus, etc.) enable integration with SCADA systems for remote monitoring and automated operation.

The interlocking system incorporates both mechanical and electrical interlocks, strictly adhering to the “five preventions” principle to avoid hazardous operations such as:

Switching disconnectors under load

Incorrect opening/closing of circuit breakers

Live earthing

Closing on earthed circuits

Unauthorized access to live compartments

Based on insulation medium, 11kV switchgear is categorized into air-insulated switchgear (AIS) and gas-insulated switchgear (GIS). AIS designs are simpler, more cost-effective, and easier to expand, while GIS models use SF₆ gas insulation for compact dimensions and superior environmental adaptability, making them ideal for space-constrained or harsh environments.

With technological advancements, some manufacturers now offer eco-friendly GIS alternatives using dry air or nitrogen mixtures instead of SF₆ to comply with environmental regulations.

2.Typical specifications and dimensions for 11kV switchgear:

Model Examples:

AIS Type:VS1 (air-insulated) KYN28A-12|HXGN15-12|XGN2-12

GIS Type: SF₆ Gas-Insulated Switchgear

Standard Dimensions (W × D × H):

Incoming/Outgoing Feeder Panel: 800mm × 1500mm × 2200mm

Bus Coupler Panel: 1000mm × 1500mm × 2200mm

PT/Metering Panel: 600mm × 1500mm × 2200mm

Riser Panel: 600mm × 1500mm × 2200mm (for vertical busbar connections)

Construction Types:

Fixed Type: All components are permanently installed; maintenance requires de-energization.

Withdrawable Type: Circuit breakers are removable, allowing hot-swap maintenance.

Modular Design: Supports flexible expansion for various system configurations.

3.11kV metal-enclosed switchgear provides the following core functions:

Power Distribution: Multi-circuit power distribution via busbar systems

Short-Circuit Protection: Rapid fault current interruption (≤60ms) by vacuum circuit breakers

Overload Protection: Graded protection through integrated overcurrent relays

Isolation Function: Visible breakpoints ensure maintenance safety

Earthing Protection: Equipped with earthing switches for safe circuit grounding

Measurement & Monitoring: Integrated current/voltage transformers for metering and monitoring

Interlocking Safety: Mechanical interlocks prevent incorrect operations

4.11kV metal-enclosed switchgear offers the following key technical advantages:

1. High-Reliability Design

Vacuum Interruption Technology: High-performance vacuum interrupters provide superior breaking capacity, long service life, and maintenance-free operation. Compared to SF₆ breakers, they are more environmentally friendly and less affected by altitude/temperature variations.

Modular Construction: Independent compartments for busbars, breakers, and cables enhance safety and maintainability. Modularity also allows flexible configurations to match system requirements.

Robust Mechanical Structure: 2-3mm cold-rolled steel enclosures with precision machining and anti-corrosion treatment ensure high strength. Type tests (including internal arc verification) validate safety under abnormal conditions.

2. Advanced Protection & Monitoring

Intelligent Protection: Multifunctional digital relays with IEC 61850 support enable digital protection and remote monitoring. Customizable settings cover overcurrent, earth faults, arc-flash, etc.

Condition Monitoring: Optional temperature, mechanical characteristic, and partial discharge monitoring provide real-time diagnostics for predictive maintenance, reducing unplanned outages.

Ultra-Fast Arc Protection: Dual optical/overcurrent detection clears arc faults in <10ms, minimizing damage. Sensors cover all critical zones.

3. Operational Safety & Convenience

Comprehensive Interlocking: Mechanical/electrical interlocks enforce “five preventions” to eliminate human errors. Logic is rigorously validated for personnel/equipment safety.

Ergonomic Design: Intuitive control panels, clear indicators, and optimized operating forces improve usability. Withdrawable breakers enable hot-swap maintenance to minimize downtime.

Visual Indicators: Voltage presence indicators, position markers, and (optionally) digital displays enhance operational awareness.

4. Flexibility & Environmental Compliance

Configurable Architecture: Fixed/withdrawable mounting, feeder/coupler/PT panel options adapt to radial/ring-main/double-busbar systems.

Environmental Adaptability: Standard indoor use, with options for heaters, ventilation, or GIS designs in harsh conditions.

Eco-Friendly: Vacuum breakers reduce greenhouse gas emissions. Materials comply with RoHS; manufacturing emphasizes resource efficiency.

5.Technology Trends

Smart Grid Integration: Increasing digitization and IoT connectivity enable cloud analytics and remote diagnostics. AI algorithms optimize protection settings.

Compact Designs: Improved insulation and materials shrink footprints. GIS models are 30-50% smaller than AIS equivalents.

Renewable Energy Support: Specialized protection logic and interfaces accommodate solar/wind distributed generation, including bidirectional flow and anti-islanding.

Detailed technical specifications for 11kV metal-enclosed switchgear:

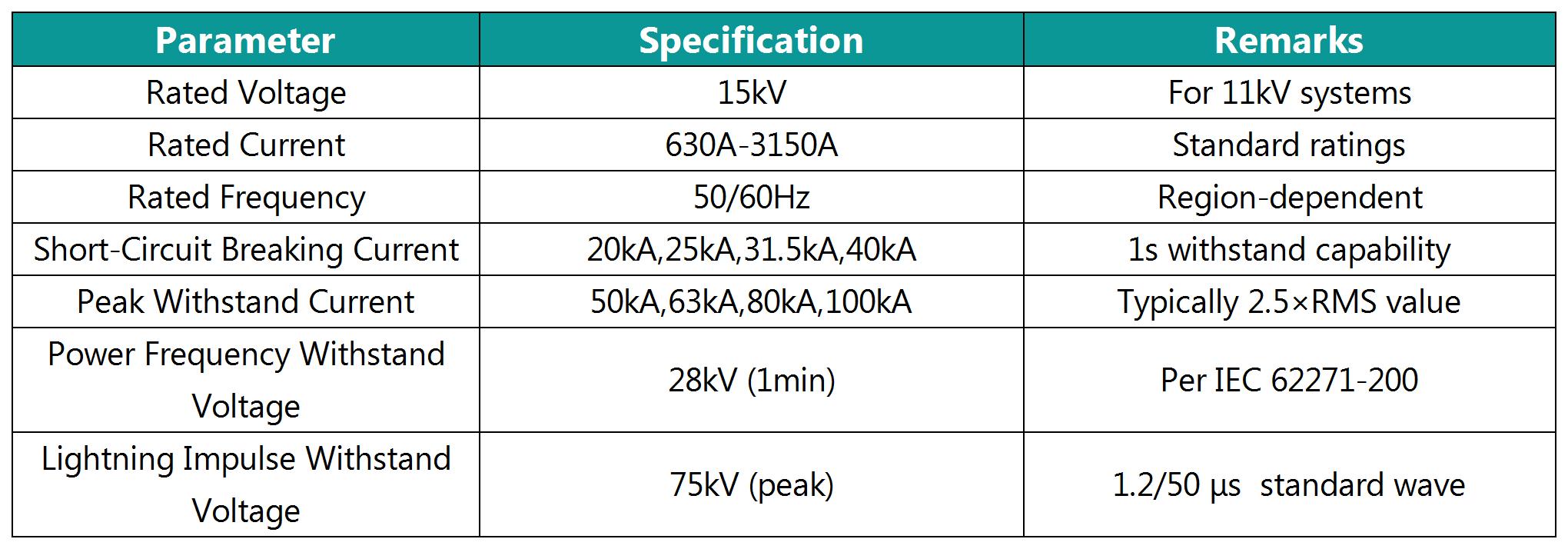

1. Rated Parameters

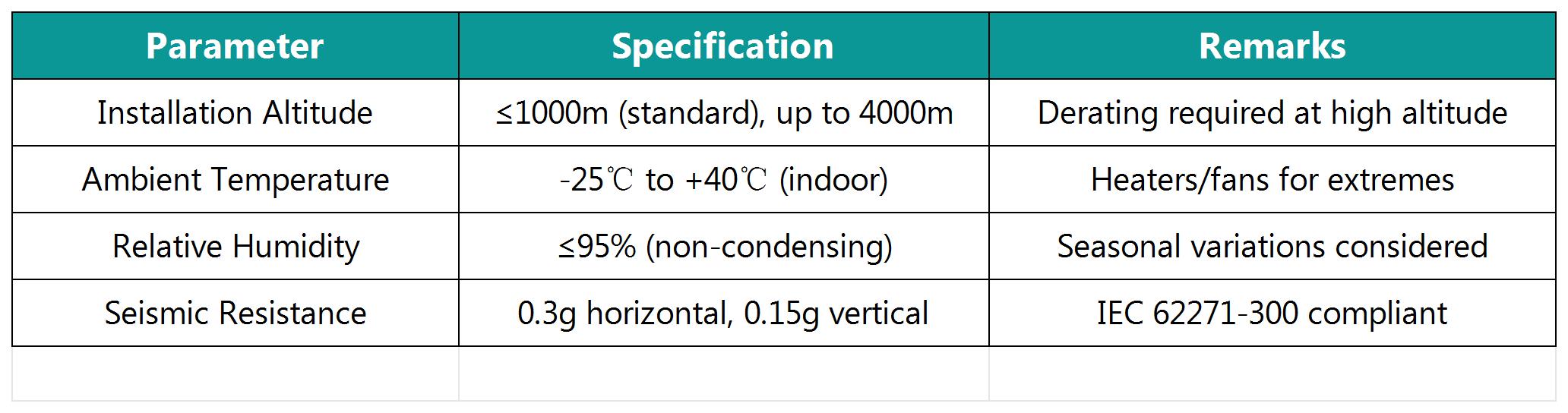

5.Environmental Conditions